Today Pujol Group faces the future with the commitment to continue promoting quality products and excellence in service to its customers.

|  |

The laminated glass sector is undergoing continuous changes and sustained growth. Due to the severe crisis in which we are subjected, companies with great adaptability to change, that decide to invest in reliable and flexible solutions, will be strengthened. These are companies that enable to adapt production to the demand curve that is generated in the market without the need to increase the cost per unit produced, while maintaining a stable profit margin regardless of the point of demand where we are. Bearing this in mind, Hornos Pujol, belonging to the Pujol Group, developed the Pujol 100 PVB + system, which is the option chosen by professionals with a greater knowledge of lamination. More than 50 of these units have already been sold around the world.

FLEXIBILITY IN LAMINATING

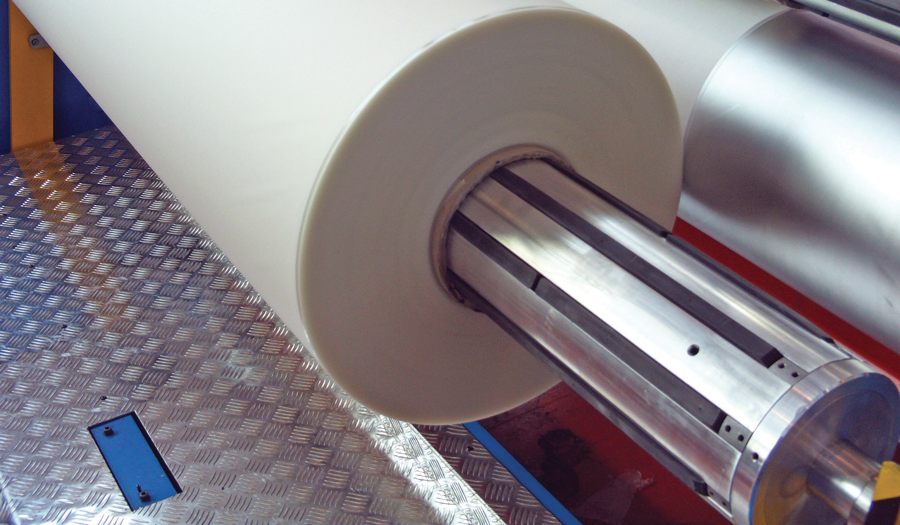

The flexibility required in the laminating processes, together with the development of new and reliable EVA-based materials, is led by the company Evalam, also integrated within the Pujol Group, located in Galicia (northwestern Spain) with a new and modern production unit of 3,500 square meters for the development, formulation and extrusion of EVA. The group is making significant investments in this factory, including two new production lines, one of them of 2.65-meter line that will allow it to respond to the increasingly frequent demand for large-format widths. These investments will make the Galicia plant the most modern EVA factory in the world. In addition, production capacity and quality of customer service will be significantly increased in a growing demand year after year.

THE BEST ‘SHOPPING’ EXPERIENCE BASED ON SEVEN BASIC PILLARS

Aware of the responsibility that leadership represents, Evalam constantly works on seven pillars that are the basis to ensure the best ‘shopping experience’ for its customers.

Part of the Pujol Group

Being part of a well-known group with an average growth in turnover of more than 18 per cent in the last five years, a history of more than one hundred years and a workforce of more than 70 workers distributed in three production plants, Pujol Group’s mission is to specialise and consolidate as a world leader in the architectural laminate market.

A wide range to cover all architectural solutions on the market

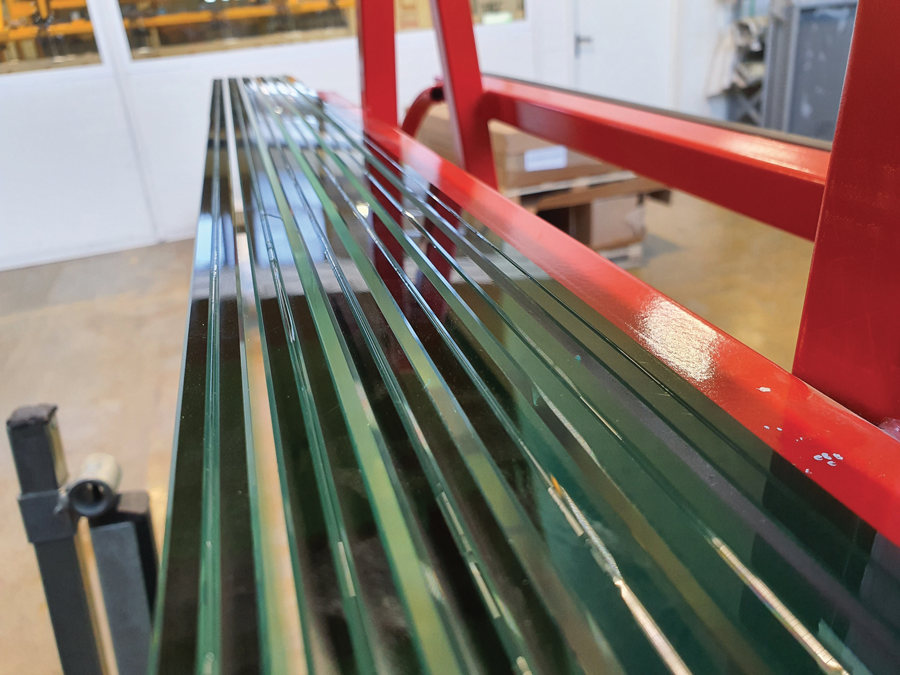

Evalam offers a wide range of EVA products, of which Evalam Visual should be highlighted. developed for laminating experts looking for a high added value solution. Its excellent and incomparable transparency, high adhesion, great acoustic insulation and a crosslink index not comparable in the market, represent perfection and make it the ideal lamination solution to be placed in all those places where optics and durability are a must.

Evalam also has Evalam N-Fluent, the latest innovation developed by the company is designed with the aim of minimizing the global costs of the post-lamination process thanks to its innovative formula it avoids the fluidity of the product and saves time and costs in edge cleaning. The time to clean the glass is clearly reduced, obtaining greater benefits for the business, without sacrificing transparency which, despite being somewhat lower than with Evalam Visual, continues to be better than any other EVA on the market. on the other hand, it has an excellent crosslink level of 85 per cent.

Completing the range of transparent EVA Evalam offers the product 80/120. It has been designed thinking of all those laminations in which it is necessary to work with temperatures that do not exceed 100ºC, such as decorative insertions with organic products. Evalam 80/120 guarantees to maintain the decorative effects of the insertions without deterioration of colours and textures due to the effect of high temperatures, maintaining the adhesion and safety performances at lower processing temperatures.

Evalam also offers a range of coloured EVA films developed to work in the temperature range of 120ºC without loss of tone at the ends and providing greater colour durability over time. They are created in contrast to those EVA films of process colour at only 80ºC that prioritize the uniformity of tone over the durability of the material. Thanks to Evalam colour and the technology used with Pujol’s laminating furnaces, both objectives are achieved: durability and colour uniformity. In addition, the range has four shades of white and one black that comply with the strict European certification for outdoor use.

The quality of the final products

Evalam controls and ensures the quality of its final products through four strict phases from beginning to end of the production process, which has allowed it to obtain ISO 9001 and ISO 14001 certifications.

Know-how of engineers and two in-house laboratories

The company’s team of eight engineers is trained to offer laboratory services for testing or product development. In addition, and as per client request, tests such as: pendulum resistance, humidity, temperature, radiation, UV filtering, peeling adhesion, resistance to the ball drop, as well as silicone compatibility can also be carried out. Evalam provides customer service and has an Architectural Technical Department that currently offers, at structural calculation level, appropriate glass dimensioning (thicknesses and layers) based on values provided by the customer.

Product certification

Evalam currently has more than 50 certificates issued by external and independent laboratories. These demonstrate the reliability of the products to different laminated compositions such as resistance to impact, humidity, radiation, acoustic insulation.

Regarding the new Building Regulations launched by the European Union and mandatory since January 2020 (EN ISO 16612: 2019-03 and EN ISO 16613: 2019-03) which refer to the resistance to the lateral load of glass and the viscoelastic properties between layers of laminated glass and laminated safety glass respectively, Evalam has achieved the highest possible classification – Class-2 for the products: Visual; N-Fluent and AB-AR (EVA based copolymer) while most Thermoplastics (PVB) are only classified as Class-1.

Reference works and unique projects

Day by day Evalam products have been worthy of the trust of the prescribers, that is why we can find Evalam solutions installed in projects for different uses, such as residential, public, or even transport. As a result of this notoriety, Evalam is already one of the options to choose from in the most important software of structural glass design and the calculation of the glass thickness on the market, such as the SJ Mepla & ProgrammaVetro.

Diversification of new products

Evalam constantly develops solutions other than EVA. In fact, Evalam has a wide range of references with regards to interlayers using different materials, such as AB-AR, thinking of applications that require additional security in public spaces or with high linear load, but above all in passive post-break safety when tempered glass is used. AB-AR is an EVA-based CO-Polymer that reinforces the standard qualities of EVA, and places AB-AR film as the Interlayer with the highest mechanical resistance performances on the market ahead of ionomers. Above all, in states of post-fracture stability above 45ºC, normal situations in glazed roofs of large commercial spaces, airports or glazed public spaces in large geographic areas where it is very common to reach these temperatures during much of the year.

I-ON BY PUJOL

Other products included in Evalam’s offer are those developed by i-On By Pujol, (a company also belonging to the Pujol Group) based on an offer of laminated glass with PDLC. i-ON by Pujol has developed PDLC (Polymer Dispersed Liquid Crystal) laminated solutions for multiple architectural applications and also to be used as a room divider that can offer transparency or privacy. A new concept of dynamic showcase is currently being developed together with the Japanese multinational Panasonic, where laminated glass with PDLC + EVA will add value to the retail and leisure sector.

PUJOL GROUP

www.hornospujol.com