Page 30 - Glass Machinery Plants & Accessories no. 6-2019

P. 30

SCIENCE AND TECHNOLOGY

Science and technology

canal through which the energy on the condenser battery W = physico-chemical changes on the

c

of the power impulse accom- 12 J, the energy emitted in the surface do not excel micrometric

panied by the formation of the interstice W = 4.8 J. sizes. Except for the initial com-

s

plasma canal is emitted. As a A universal microscope was ponents of the processed materi-

result of the interaction between used to measure the level of wear al, a considerable quantity of car-

the plasma canal and the surface as it allows measurement with bon (about 90 per cent) has been

of the tool-electrode, the graphite an error of 1μm. To begin with found. The analysis of transversal

erodes and is transferred to the we measured the diameter in microfiling microstructure shows

piece surface where the graphite ten points of two newly pro- that part of the carbon trans-

pellicle is formed. Modifications duced transverse plates estab- ferred onto the piece surface dif-

of the physico-chemical proper- lishing the sign point zero. A fuses in its depth at depths of

ties in the processed superficial transverse plate was covered with micrometer order. We can sup-

layer take place simultaneously a graphite pellicle and subjected pose that new phases are being

under the deposition pellicle. to dimensional measurements in formed including those of car-

The glass moulding form the same ten points as in the bides of alloy components used

transverse plate is made of cast newly produced one; the pro- to manufacture the piece and of

iron, the tool-electrode repre- cedure was repeated after the those of graphite on its surface.

sents a bar with the diameter transverse plates were included These lead to physico-chemical

equal to 3mm made of electro- in the glass product fabrication modifications of the part material

technical graphite of the type flux in Chisinau Glass Factory. and of those of exploitation.

MPG-6. Previously experiments For the newly made transverse In the paper, transverse plates

carried out on steel demonstrated plate (sample 23) 39900 cycles were tried under real conditions

that the micro-durability of the (75 hours). The cycle frequency of exploitation and it was stat-

affected layer increases consider- constitutes v=8.75 cycles per ed as a result that the trans-

ably. minute. The temperature of the verse plates of moulding forms

In order to obtain the minimal glass drop 1129°C; the glass used on whose active surface graph-

roughness of a uniform graphite was of the BT-1 type whose ite pellicles were formed func-

pellicle and high durability of chemical composition according tioned in 57600 cycles during the

the transverse plate surface, the to the standard SM GOST R absence of form and dimension

following processing regime was 52022-2004. modifications.

selected: the charging power of Thus experimental investiga-

the condenser battery of the cur- RESULTS AND ANALYSIS tions in the technological cycle

rent impulse generator U = The analysis of processed sur- were performed to compare the

c

200 V, the size of the interstice face morphology has shown that wear of transverse plates of glass

S = 1mm, the condenser moulding forms. Two transverse

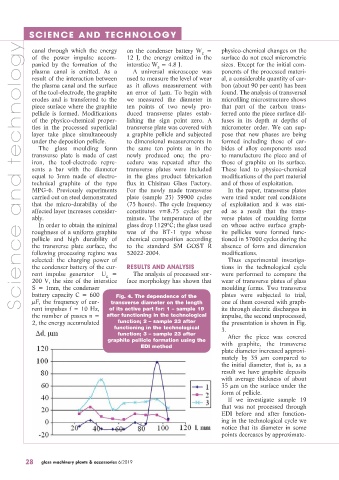

battery capacity C = 600 Fig. 4. The dependence of the plates were subjected to trial,

μF, the frequency of cur- transverse diameter on the length one of them covered with graph-

rent impulses f = 10 Hz, of its active part for: 1 – sample 19 ite through electric discharges in

the number of passes n = after functioning in the technological impulse, the second unprocessed,

2, the energy accumulated function; 2 – sample 23 after the presentation is shown in Fig.

functioning in the technological 3.

function; 3 – sample 23 after After the piece was covered

graphite pellicle formation using the with graphite, the transverse

EDI method

plate diameter increased approxi-

mately by 35 μm compared to

the initial diameter, that is, as a

result we have graphite deposits

with average thickness of about

35 μm on the surface under the

form of pellicle.

If we investigate sample 19

that was not processed through

EDI before and after function-

ing in the technological cycle we

notice that its diameter in some

points decreases by approximate-

28 glass machinery plants & accessories 6/2019