Page 28 - Glass Machinery Plants & Accessories no. 6-2019

P. 28

SCIENCE AND TECHNOLOGY

Science and technology

EDI

application

in increasing

durability of

glass moulds

elements

This article shows how, thanks to

the continuous work of The Chisinau

Glass Factory and the State University

of Balti, a graphite layer deposited

on the surface of the transverse

plate simultaneously performs a

series of functions that include anti-

wearing protection, also increasing

refractability, and much more.

he Chisinau Glass Factory surface hardening simultaneously

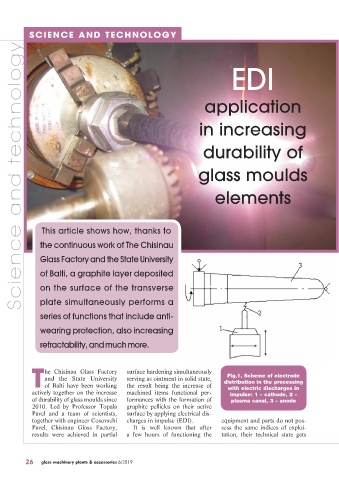

and the State University serving as ointment in solid state, Fig.1. Scheme of electrode

Tof Balti have been working the result being the increase of distribution in the processing

with electric discharges in

actively together on the increase machined items functional per- impulse: 1 – cathode, 2 –

of durability of glass moulds since formances with the formation of plasma canal, 3 – anode

2010. Led by Professor Topala graphite pellicles on their active

Pavel and a team of scientists, surface by applying electrical dis-

together with engineer Cosovschi charges in impulse (EDI). equipment and parts do not pos-

Pavel, Chisinau Glass Factory, It is well known that after sess the same indices of exploi-

results were achieved in partial a few hours of functioning the tation, their technical state gets

26 glass machinery plants & accessories 6/2019