When Viprotron opened in 2004, the focus of its defect detection scanners was on the insulated glass market. While improving and refining scanning technologies, the company product range broadened to include cutting, fabrication, lamination and tempering. In 2017 Viprotron launched the first ever Anisotropy and Haze Scanner in the market. In the USA, this breakthrough development was awarded as the most innovative equipment of the year.

At Glasstec 2022, Viprotron added a rollerwave and edge kink evaluation function to its lineup. All five functions will be available in one complete package – TEMPER SCANNER 5D – or as individual scanners: Rollerwave/Edge Kink, Anisotropy, White Haze and optical high contrasted defects as well as coating defects.

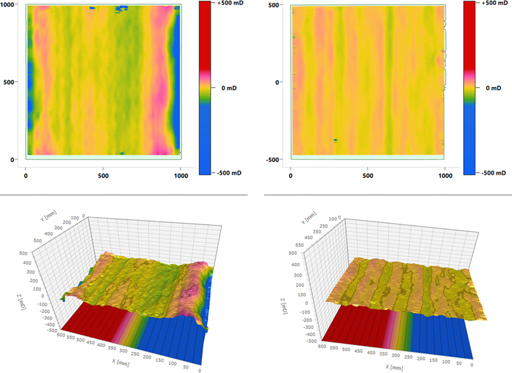

Although in the last few years furnace manufacturers have improved their processes, the Rollerwave and Edge Kink evaluation will still be of great interest. The need to increase productivity often results in furnaces being utilized to the limits of production. That sometimes leads to lower product quality. In order to reliably operate the furnaces at the limit of their capacity, good measuring instruments are required. This is especially necessary for optical distortion, which does not only lead to a wavy appearance in the final product – but brings issues along when the sheets will be assembled to laminated or insulated glass.

In addition to the data that glass processors could already obtain from the haze or anisotropy control, the measurement of optical distortion now provides additional information. All these components can contribute to a significant improvement in furnace control and thus to better product quality at high productivity.

The special feature of Viprotron’s solution is that the quality of the furnace exit rollers will no longer play the decisive role. While solutions currently on the market still require the use of special rollers that ensure uniform glass transport and a certain light trap, Viprotron’s development focuses on a process that is as independent as possible from the physical appearance of the exit conveyors. An expensive retrofit of the outlet section would then be obsolete, and the tempered glass manufacturer can adapt his existing furnace outlet to the new function with only little effort.

The new scanner is therefore not only available for new furnaces, but also as a retrofit for older models.