The OPTIMELT™ Thermo-Chemical Regenerator (TCR) system stores waste heat from the hot oxy-fuel flue gas in regenerator beds and uses this energy to reform a mixture of natural gas and recirculated flue gas to hot syngas which is combusted with oxygen in the furnace. This technology significantly reduces the natural gas consumption of the oxy-fuel furnace. Following successful commercialization on a 50 tpd container glass furnace in Mexico, the OPTIMELT™ system has been in commercial operation on a 110 tpd oxy-fuel fired tableware glass furnace at Libbey Leerdam in The Netherlands since November 2017.

|  |

Van Valburg M.a, Schuurmans F.a, de Diego J.b, Laux, S.c, Chakravarti S.c.

aLibbey Holland, Lingedijk 8, 4142 LD Leerdam, The Netherlands

bNippon Gases Euro-Holding S,L.U., Orense 11 9ª, Madrid 28020, Spain

cLinde Inc. (formerly Praxair, Inc.), 10 Riverview Drive, Danbury, CT 06810, USA

INTRODUCTION

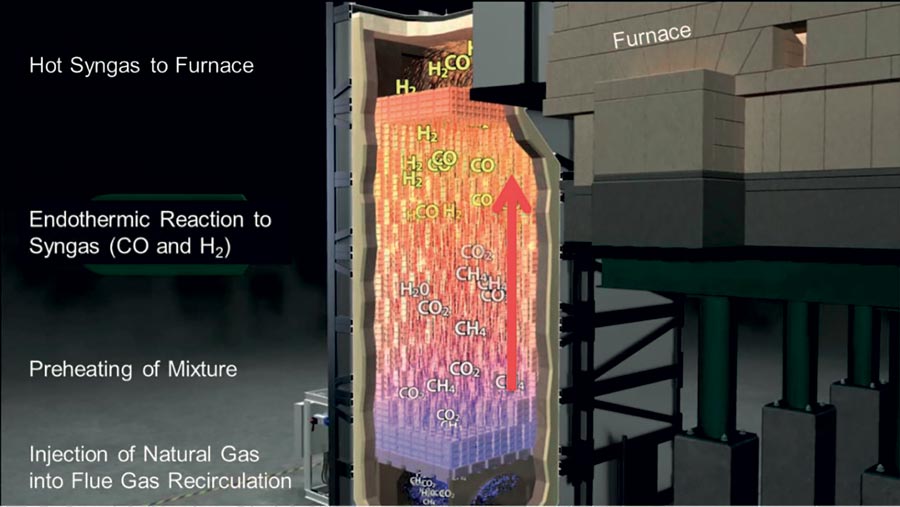

The OPTIMELT™ Thermo-chemical Regenerator (TCR) process is an advanced heat recovery technology for oxy fuel fired glass furnaces. The technology is based on a unique waste heat recovery concept called thermo-chemical regeneration in which heat stored in a regenerator checker during the flue gas exhausting cycle is recovered during the reforming cycle by preheating and reforming a mixture of natural gas and recycled flue gas.

Figure 1 shows this cyclic heat recovery process.

The flue gas cycle in regenerator 1 is similar to the conventional regenerator heating cycle in which flue gas waste heat is transferred to and stored in the checker. The unique feature of the TCR process occurs during the reforming cycle where a portion of the cooled flue gas is recycled back (Recycled Flue Gas, RFG) to the bottom of the already preheated regenerator (regenerator 2) and mixed with natural gas fuel (e.g., CH4). The RFG/CH4 mixture is heated by the hot checker. When the gas mixture is heated above a certain temperature various endothermic chemical reactions occur. For example, CH4 is reformed by CO2 and H2O in the RFG to form CO and H2.

The reformed gas or “syngas”, Figure 2, is combusted with oxygen in the glass furnace, Figure 3, thus providing thermal energy for glass melting. When the regenerator in reforming mode is getting colder, the regenerators are switched and the regenerator that was previously in reforming mode is heated with flue gas.

OPTIMELT INSTALLATION ON THE TABLEWARE FURNACE AT LIBBEY LEERDAM

In support of Libbey’s sustainability strategy and alignment with the European Carbon Reduction Roadmap the project’s goals were to utilize best-in-class furnace technology for improved productivity, reduce energy consumption and lower emissions.

The new furnace started production with oxy-fuel combustion in the spring 2017 and the TCR startup followed in November 2017. The OPTIMELT part of the project was awarded funding by the European Union under LIFE grant LIFE15 CCM-NL-000121 – LIFE OPTIMELT.

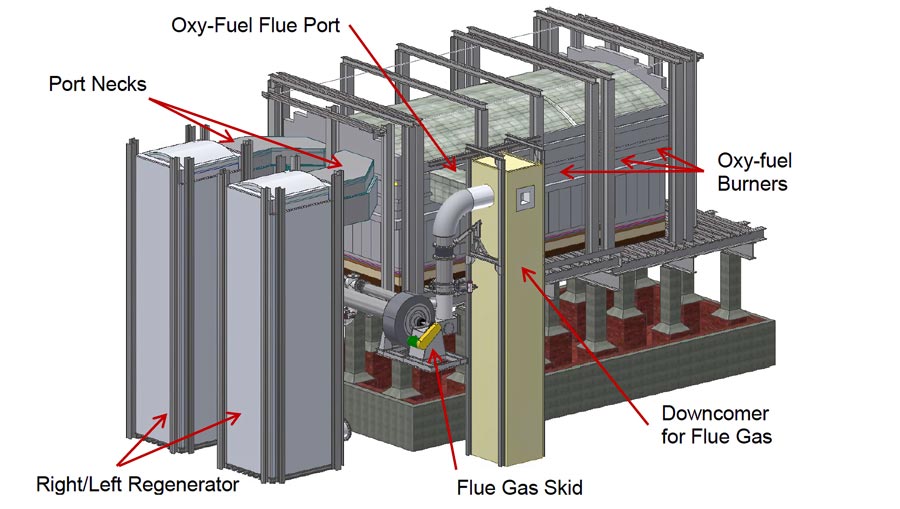

Figure 4 shows the typical end-fired arrangement of the furnace with the TCR regenerators, flue gas piping and the downcomer with the flue gas damper at Leerdam. The flue gas recirculation piping is arranged under the port necks. Between the downcomer and the furnace a cooled refractory damper is used to close the flue gas opening during TCR operation when all flue gas passes through the regenerators. When the furnace operates on oxy-fuel, this flue gas damper is opened, and air dilution cooling is used in the downcomer to quench the flue gas to the baghouse inlet temperature. The oxy-fuel combustion system is a completely redundant back-up to the TCR system.

During OPTIMELT operation, the flue gas leaves the furnace through the regenerator that is in heating mode. A small high temperature fan is used to move most of the flue gas to the downcomer where it is diluted with air to a temperature suitable for the downstream flue gas treatment system where a main fan after a baghouse moves the flue gas to the stack. Approximately 20 per cent of flue gas is recirculated after the fan to the opposite regenerator, where it is mixed for reforming with natural gas at the entry to the regenerator. This mixture is then reformed to syngas and directed through the port neck into the furnace where oxygen jets below the port provide oxygen for combustion. During this TCR operation the hot flue gas damper inside the downcomer is closed and all flue gas is directed through the TCR system.

A significant part of the project was a comprehensive approach to process and system design safety. This was followed by a safe and successful implementation of the technology at Leerdam and the startup. The process and implementation safety steps were reported in [1].

GENERAL PROJECT EXPERIENCE

The OPTIMELT execution was integrated into the overall project and careful planning resulted in a successful startup and optimization without lost production[2]. Early and comprehensive training of the engineering and operation staff on the new OPTIMELT technology resulted in good project acceptance and ownership. The switching between oxy-fuel and TCR operation is seamless and is either initiated by operator demand or automatically if there is a system fault.

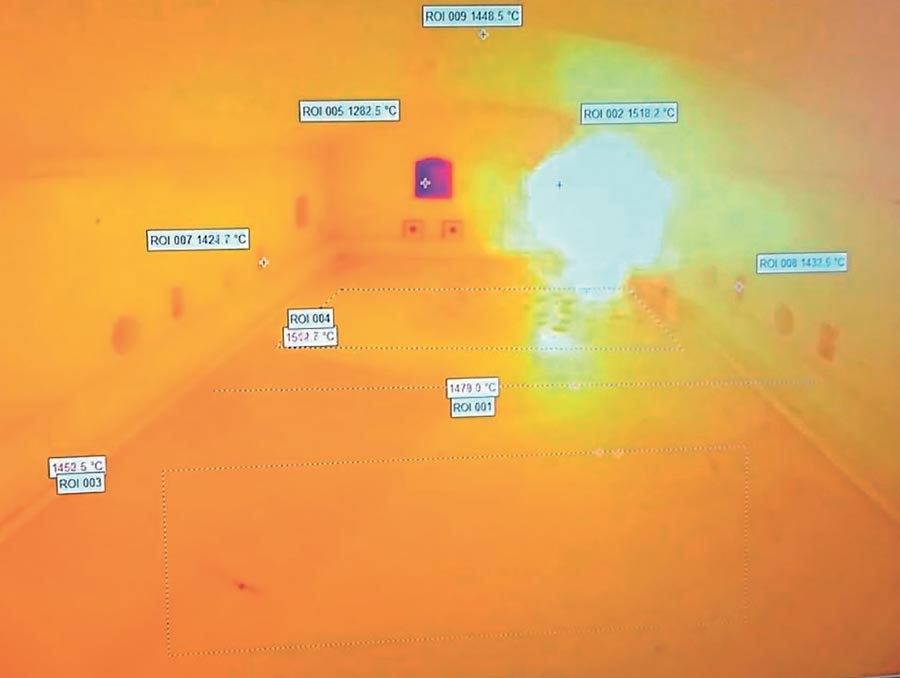

The previous operational experience with generating large TCR syngas flames as needed for melting high quality glass has been confirmed at Leerdam. The oxygen jets can be directed in such a way that the syngas flame in the furnace has the appropriate length and width and is not touching walls or crown. There are no signs of overheating furnace refractory. The same glass quality at the required pull rates can be achieved and the required differences in operational settings in comparison to oxy-fuel operation have been identified for the OPTIMELT technology.

HEAT RECOVERY PERFORMANCE

The OPTIMELT technology recovers energy contained in the flue gas. The TCR system basically works as a heat exchanger. If the flue gas temperature of the gas entering the regenerators is lower, the available total amount of heat to be recoverable by reforming is limited as well. Any heat lost from the flue gas through the insulation in the high temperature parts of the port necks or direct furnace flue gas leaks cannot be utilized for the syngas generation process and reduces the energy reduction potential of the TCR system. Also important for the recovery are the pull rate of the furnace and the throat temperature which influence the total required heat input and the furnace flue gas temperature level. Batch composition and moisture, cullet ratio, air infiltration, excess oxygen level and even oxygen supply purity are related to the amount of flue gas available and influence the flue gas enthalpy and energy savings potential.

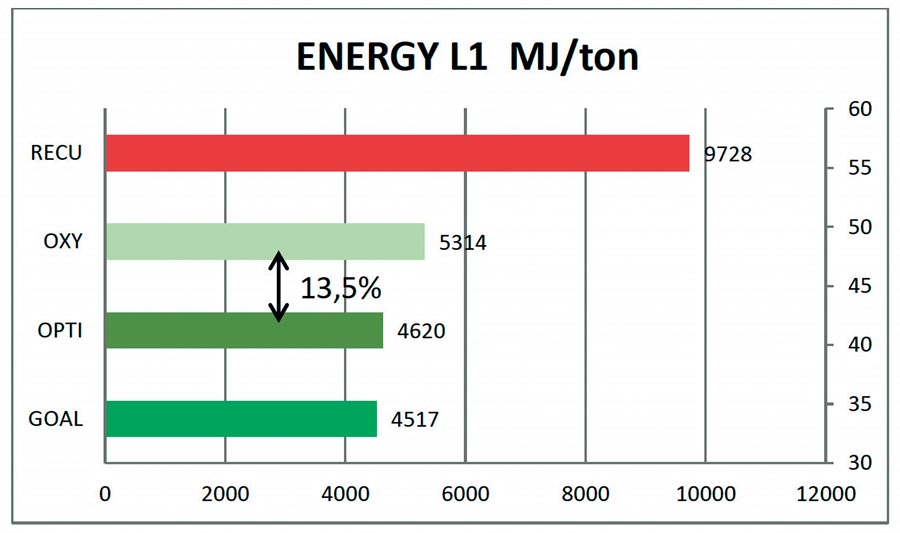

The first results of the energy consumption are shown in Figure 5 which shows the specific fuel consumption for oxy-fuel and TCR operation in MJ/t normalized to 50 per cent cullet rate and 25°C ambient temperature (to eliminate summer/winter influence) versus the pull rate of the furnace. Each point represents a daily average of the energy consumption. Due to daily variation of the furnace production rate at Leerdam and process optimization settings the data scatter is quite large.

Most of the data points fall into a production range of approximately 75 per cent of the furnace capacity. At this pull level the reduction in heat consumption is 13.5 per cent which falls short of the expected performance. At a low furnace production rate, the furnace temperatures are lower and the recoverable heat in flue gas by TCR is reduced. Thus, the heat recovery rate is expected to increase with the furnace production rate. Although the available data at higher pull of 85 per cent capacity is limited, it shows approximately 15 per cent fuel reduction.

EMISSION PERFORMANCE

The L1 project has significantly reduced the emission of NOx, SOx and dust at Leerdam. Table 1 shows preliminary and non-official emission measurements.

By replacing the two old air recuperative furnaces at the site with a single oxy-fuel furnace the NOx emissions were reduced from 1.63 kg/t (3.2 lb/ton (US)) to 0.39 kg/t (0.8 lb/ton) or by 76 per cent. Similar reduction percentages were achieved for SOx and dust. The OPTIMELT emission performance goes beyond that of the oxy-fuel combustion system. NOx, SOx and dust were reduced in these first preliminary measurements by approximately 80-90 per cent compared to the old furnaces. The unique forming of the large TCR flame with oxygen jets in the furnace leads to a deeply staged flame where most of the fuel and oxygen can be diluted with furnace gases before they react with each other.

The excellent results for SOx and dust show that the OPTIMELT flame is properly placed in the furnace and that glass volatilization is low. CFD models of the two combustion systems have confirmed the lower volatilization rates and that the furnace temperatures are generally lower with the TCR flame.

Initial data from 2017 without burner optimization show higher NOx emissions in a range of 0.59 to 0.85 kg/t. However, with a well optimized combustion NOx emission of approximately 0.40 kg/t (0.80 lb/ton) are possible with oxy-fuel operation and 10 per cent flue gas nitrogen content. The data points for OPTIMELT operation were collected at a slightly higher range of nitrogen concentrations in the furnace but are all below a NOx emission of 0.3 kg/t (0.6 lb/ton). NOx emissions with OPTIMELT operation of 0.2 kg/t are remarkable since Dutch natural gas contains about 14 per cent nitrogen. It is our expectation that by working closely with glass plant operators and managing air infiltration, the OPTIMELT technology can meet future emissions requirements while recovering flue gas energy from oxy fuel furnaces.

CONCLUSION

The implementation of the OPTIMELT technology into the furnace at Libbey Leerdam has been successful and the system is now in commercial operation using a fully automated control system. The project commissioning and startup phase were completed without encountering major issues or glass production problems. A few design issues had to be addressed, but no fundamental technology or scale-up issues were encountered. The operational results show that the projected energy savings can currently not be achieved due to unexpected heat losses in the regenerators which especially penalize smaller systems as the recoverable energy is limited. The shortcomings of the insulation will be addressed in the future. The emission results of the L1 TCR system are significantly lower than the already low emissions of the oxy-fuel combustion system. Future optimization progress and operational experience will be available as part of the reporting requirements under the LIFE grant.

The support of the European Union for the implementation of OPTIMELT at Libbey Holland is gratefully acknowledged.

REFERENCES

- M. van Valburg, E. Sperry, S. Laux, R. Bell, A. Francis, and H. Kobayashi, “Design and Implementation of OPTIMELT™ Heat Recovery for an Oxy-Fuel Furnace at Libbey Leerdam”, 78th Conference on Glass Problems, Columbus, OH, October, 2017.

- M. van Valburg, F. Schuurmans, E. Sperry, S. Laux, R. Bell, A. Francis, S. Chakravarti and H. Kobayashi, “Operating Experience with the OPTIMELT™ Heat Recovery Technology on a Tableware Glass Furnace”, 79th Conference on Glass Problems, Columbus, OH, October 2018.

Royal Leerdam / Libbey Europe