Thanks to more than 25 years of experience, dynamism, competence and motivation, Optima has continued to develop software for companies of the flat glass sector, with more than 20,000 global installations. In the present Industry 4.0 era, the company is now active in Information Technology, with software aimed at the complete control of production.

|  |

In the era of Industry 4.0, companies increasingly need to automate and monitor production processes in real time and from this point of view, software certainly plays a crucial role in the integration and communication between the different types of systems present in glassworks: cutting lines, processing machines, CNC, furnaces and so on.

EXPERIENCE AND PROFESSIONALISM; DYNAMISM, COMPETENCE AND MOTIVATION

Founded in 1994 thanks to the experience and professionalism of the founding members, Optima is the result of the synthesis of dynamism, competence and motivation: the company is now active in the Information Technology sector applied to the processing of flat glass in particular and, in general, to all machine tool machining on flat surfaces.

A highly qualified team of professionals provides prompt and decisive answers to meet the needs of international customers.

The company boasts more than 20,000 installations all over the world thanks to a widespread sales network (three international offices: Spain, Canada and China, and more than 20 international collaborators, including agents and dealers).

ERP AND MES SOFTWARE SOLUTIONS

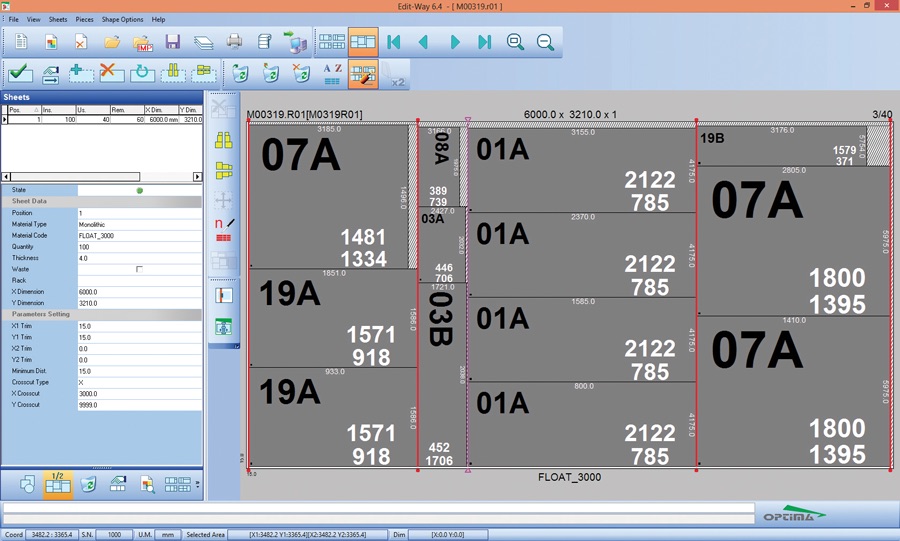

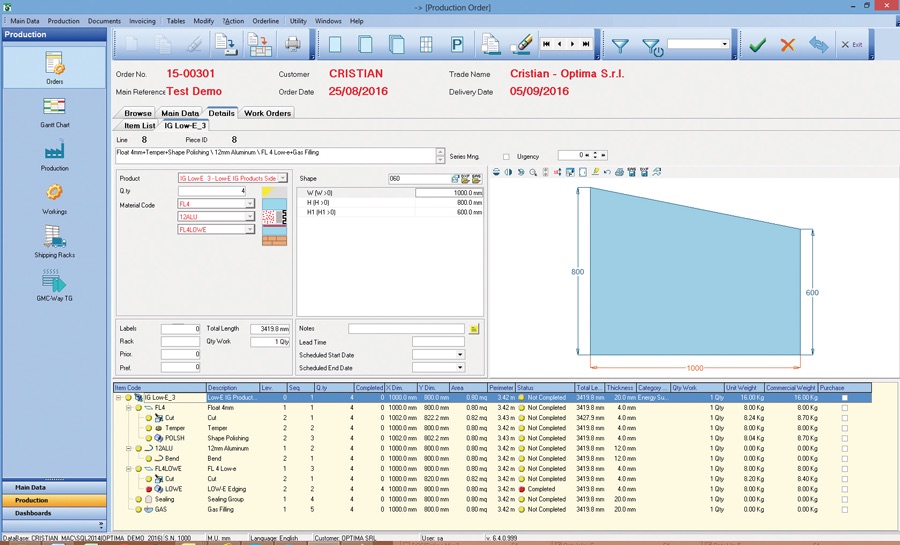

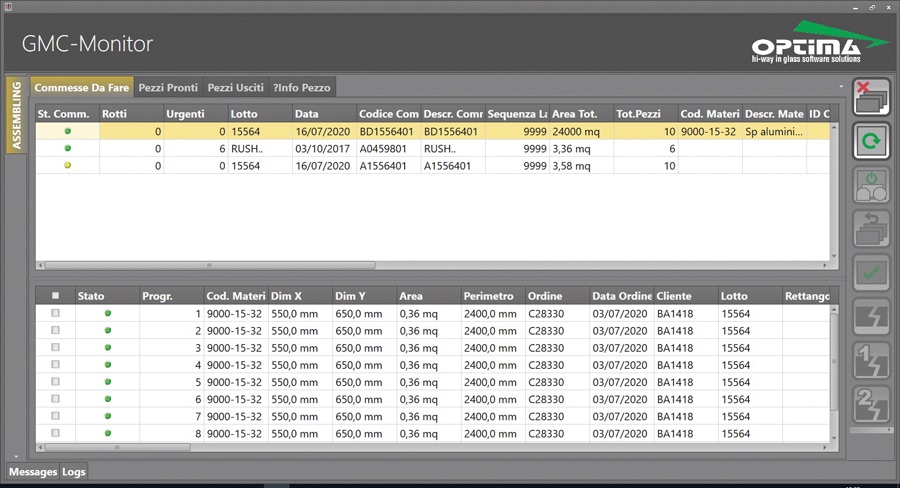

For over 25 years, Optima has been developing ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) solutions capable of managing the entire business cycle and glass production: from the purchase of raw materials, accessories and consumables, to the realization of estimates, orders; from the production scheduling for the optimal management of the plants in relation to the production batches, to the unloading and handling on trestles, automated or manual up to the delivery to the customer with the issue of bills and invoices, up to the energy certifications and the issue of DOP (thanks to integration with the glassAdvisor system).

NATIONAL AND INTERNATIONAL COLLABORATION

Another strong point of Optima is, and has always been, its collaboration with national and international manufacturers that generates a fruitful environment for the development of software solutions capable of guaranteeing improvements in production efficiency, integrating and automatically sending information on what must be done in the various lines and receiving automatic feedback on the execution and timing of the specific phase. Management, therefore, aimed at the complete control of production, including scheduling and initial planning.

PRODUCTION EFFICIENCY

Again in terms of production efficiency, Optima software is integrated with GLASSInspector by DeltaMax Automazione, an Italian company leader in the production of scanners for the detection of defects, allowing interfacing with production, as well as data processing for the creation of statistics. and production reports for ad hoc quality control.

Benefits:

- increased productivity and efficiency;

- reduction or elimination of insertion times and the use of paper;

- lead-time reduction;

- organisational improvement of processes.

Optima Srl

www.optima.it