Fratelli Pezza started its activity as a supplier to the petrochemical and textile industry for light and heavy carpentry work. It soon specialized in the design and manufacture of machinery dedicated to glass processing, and, in particular, sandblasting machines for flat glass, of which it has been the undisputed market leader for over 30 years.

|  |

AN IMPORTANT RENOVATION IN RECENT YEARS

Fratelli Pezza has always stood out for its compulsive attention to detail and the general quality of its products, as well as for the unceasing technological development that has allowed it to implement new operational features, as well as improving existing ones.

Investments did not stop at products alone; in fact, in recent years, the company has carried out a total renovation of its headquarters, gaining in organization and production efficiency, as well as in terms of corporate representation.

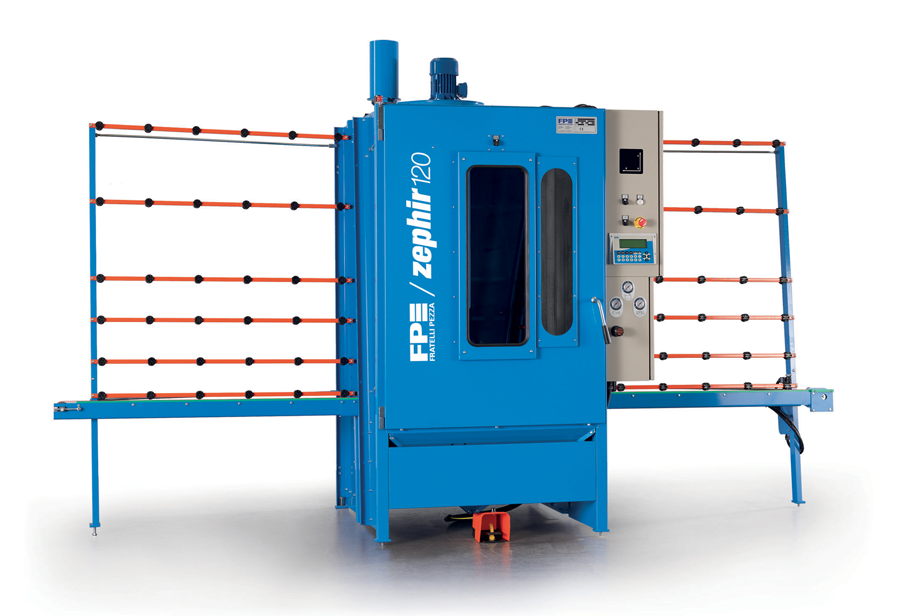

AUTOMATIC SANDBLASTERS: THE ZEPHIR AND MINSTRAL EV SERIES

The range of Fratelli Pezza automatic sandblasters is vast and varied, and truly adapts to the needs of any customer. It consists of two series: the Zephir series, simple and cost-

effective, and the Mistral EV, equipped with top-of-the-range features.

The Zephir Series

The Zephir is available in two varieties, the Z120 (maximum working height 1200 mm) and the Z180 (1800 mm), which can be equipped with one or two automatic guns.

This line of sandblasters carries out normal, light sandblasting and deep engraving, always maintaining high quality standards. Additionally, the software enables to programme a certain number of sandblasting passes in automatic mode, so that it excavates the glass without having to move it in and out of the cabin.

The Zephir is widely used for double-glazing, as it represents the ideal solution for those who want to recover glass with slight surface imperfections; nonetheless, it is also suitable for decorative designs. Thanks to the extremely competitive prices of the Zephir models, the glassworks can have excellent economic return with a little investment.

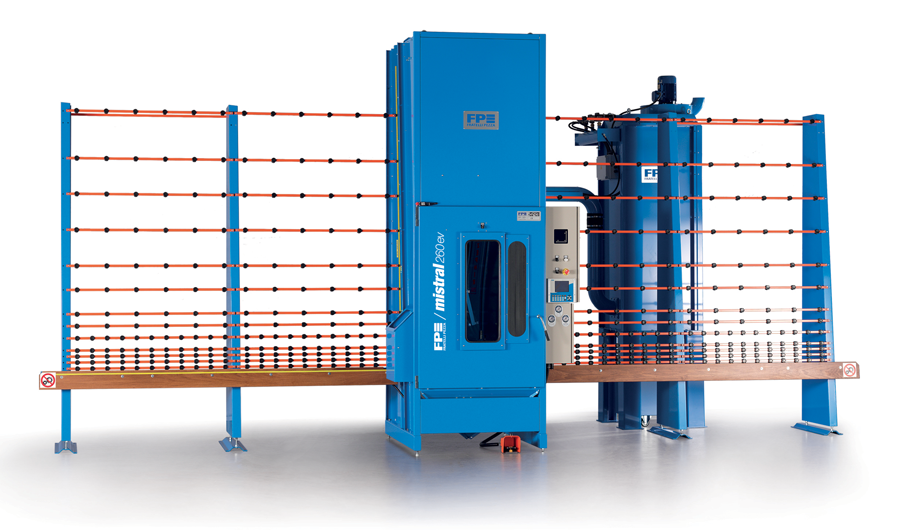

Mistral EV Series

In addition to the working features of the Zephir, The Mistral EV series enables to carry out shading blasting and to set up to 50 blasting areas on the glass plate. This feature provides a wide range of solutions for the decoration of doors, partition walls, and other architectural elements, and allows remarkably reducing process-time, especially in case of mass production of glass or mirrors that need to be sandblasted only in certain parts of their surface.

The shading-blasting feature is widely used by customers involved in the production of shower cubicles, glass railings, balustrades and many other modern design solutions.

A NEW EFFICIENT INTERNAL SYSTEM

All Fratelli Pezza sandblasters are equipped with a built-in high efficiency filtration system, which does not require additional external units such as the cyclone separator. It has a unique system, which prevents the accumulation of static electricity within the cabin. The Mistral EV series is available in three models: M120EV (maximum working height 1200 mm), M180EV (1800 mm) and M260EV (2600 mm).

All cabins are equipped with:

- Colour display

- Newly enhanced software

- “Pause & check” feature – which allows to stop the working programme and then restarting it at any moment of the process, without jeopardizing the finish quality.

- Preventive maintenance warnings – which appear on the screen whenever an item needs to be checked and possibly replaced.

Sandblasters designed by Fratelli Pezza are characterized by the lowest power and compressed-air consumptions among the equipment available on the market and provide great productivity and an excellent finish quality.

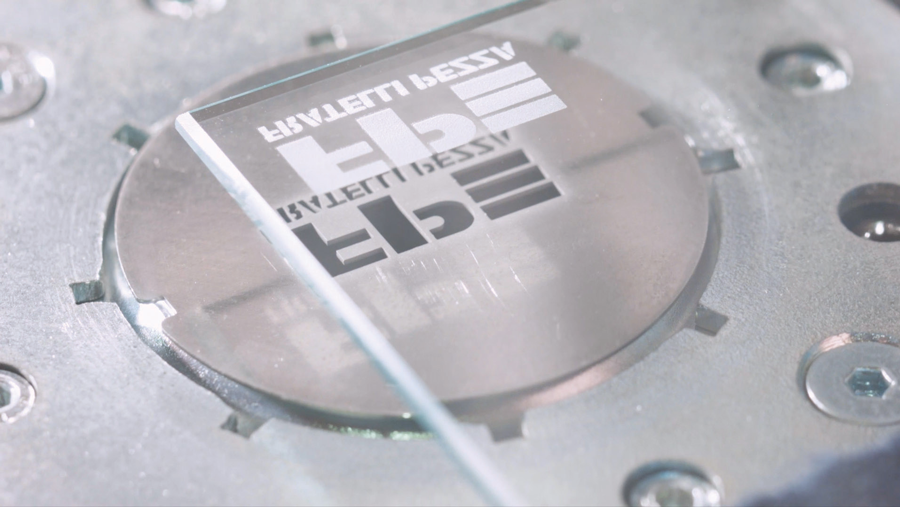

EASYMARKER SERIES – THE INNOVATIVE SAND-JET MARKING EQUIPMENT

Given the growing demand of marking on glass, the Italian company has devoted resources and energy to the development of a complete line of sand jet marking equipment. This is a result of the increasingly stringent regulations, with special regard to the glass-items used in the building sector.

The product range includes two manual and portable devices and two fully automatic equipment, the Easymarker series:

Easymarker UP is suitable to be combined with horizontal machines, while the Easymarker EV version has been designed to be coupled with vertical machines.

Any Easymarker can be activated automatically by connecting it with any other glass-working machine. These are the ideal solution for companies with large numbers of production.

The portable versions are extremely flexible. The company’s R&D department have developed a new version of the product, the new Marker 301T. This allows imprinting a mark with a diameter of up to 30 mm on the surface of glass and mirrors, ensuring the same quality and sharpness of marking of the standard M101T version.

The new Marker 301T responds to the needs of any company required to comply with dimensional standards imposed by the regulations or provisions of their industrial group, or simply those who, through the marking, must convey a large number of information while maintaining high sharpness of each word or number.

With the aim to continuously update and improve their products, Fratelli Pezza have equipped the machine with a new highly sensitive timer, which enables to further optimize the lifespan of the stainless steel masks where the customer’s logo is engraved.

Fratelli Pezza marking devices provide a clear, sharp and permanent mark, and can be used on any type of glass. Additionally, the portable models and the Easymarker EV allow marking the edge of the glass, if the thickness makes it possible.

MIX 30 PRO, PROTECTIVE COATING FOR SANDBLASTED GLASS

Taking advantage of their wide experience in the field of sandblasting on glass, Fratelli Pezza have introduced the Mix 30 PRO, an enhanced version of Mix 30, the well-known protective coating for sandblasted glass that the company has been selling for many years.

The new formula maintains the best qualities of the older version, whilst additionally ensuring higher efficacy and reduced drying times. The product can be spread easily with a simple microfiber cloth and it does not leave stains or halos.

GHOSTGLAZE

Ghostglaze is a brand-new specific product for the protection of transparent glass, therefore non-sandblasted or treated. Ghostglaze was created to protect the glass surface, by making it water-

repellent and highly weather-resistant, without altering its mechanical and aesthetic characteristics.

Ease of application, quality of protection and a highly competitive price make Ghostglaze the ideal product for float glass, shower enclosures and any other type of untreated glass, to protect the surface and facilitate cleaning.

EXCELLENT CUSTOMER RELATIONS

Fratelli Pezza’s e-shop offers its customers an optimal service through which it is possible to order accessories and spare parts quickly and easily; customers can register their machines in the portal so that the system only displays articles which are suitable for that model, thus avoiding the view of erroneous items.

Fratelli Pezza take advantage of an international distribution network, and offer customers top-level after-sales service, from both technical and commercial point of view.

Fratelli Pezza Srl

www.fratellipezza.com

shop.fratellipezza.com