Autor: Niki Ester – Software Manager, Bucher Emhart Glass

“Twenty years ago, detecting bird swings anywhere on a glass container was considered difficult. No system on the market could find all of the defects reliably. Glassmakers lived with this and managed the risks knowing that the automated inspection equipment installed on their lines could not get all of the defects. Today, if a machine cannot find all bird swings, it’s out.”

I recently overheard a conversation between glass industry technicians that summed up the general development of automated inspection technology over the last decades very well. “Bird swings have always been critical defects. We just did not have a good way to detect them, so we lived with it and managed the risk. However, as technology improved and it became possible to detect these defects reliably, detecting these defects became a strict requirement for every inspection line.”

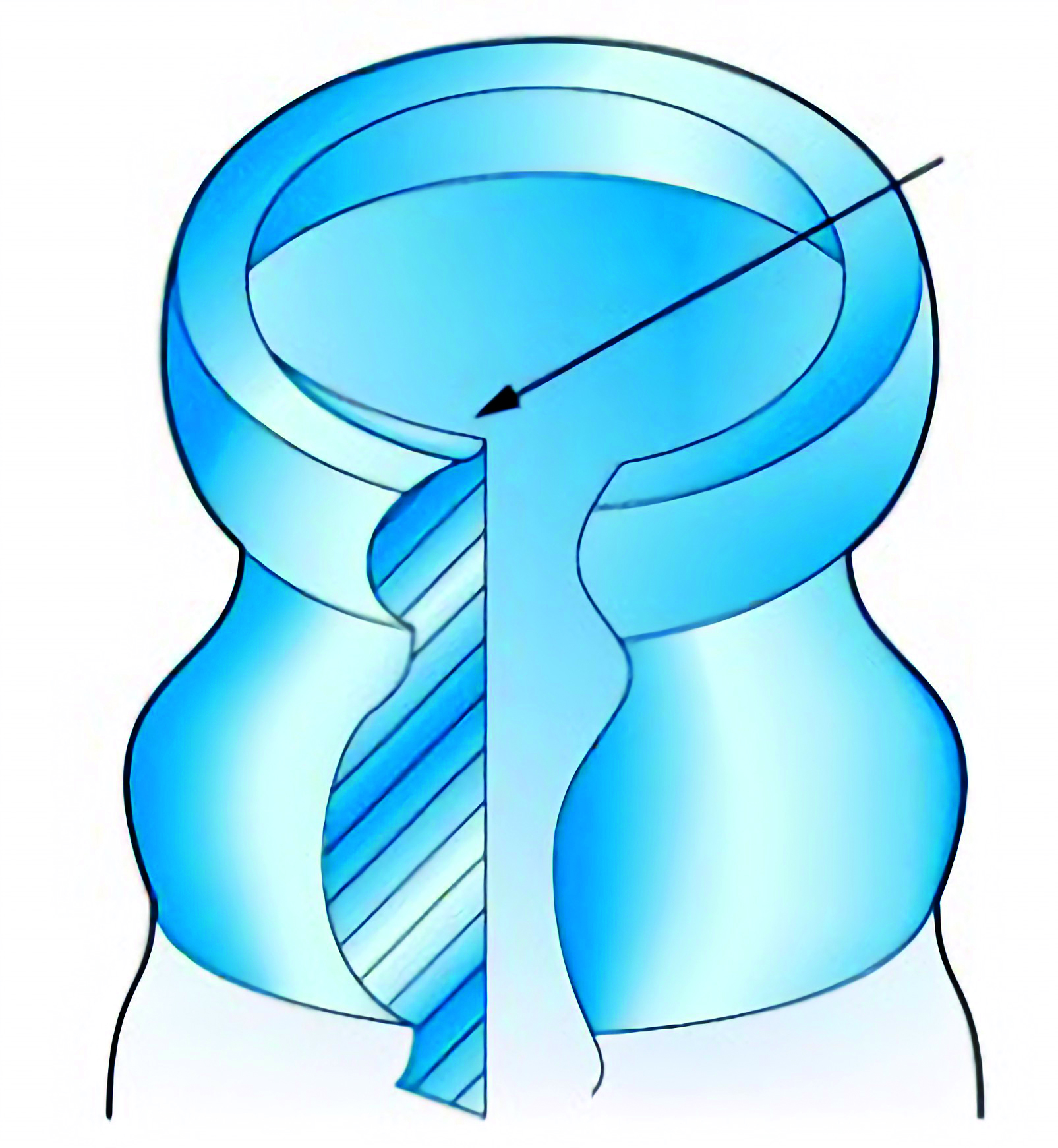

A recent example where the quality limits and expectations to detect critical defects has increased with inline inspection equipment is the so-called “Wire Edge” defect. A Wire Edge is excessive glass projecting upward from the inside edge of the finish where the guide plate and neck ring parting line is formed.

Historically, Wire Edge defects were hard to set up and detect. Even with a perfect optical

set-up, some defects would slip through, or glassmakers would suffer from the loss of commercially acceptable ware.

Scout AI technology

Today, utilizing SCOUT AI technology, these Wire Edge defects are detected with absolute reliability and controlled at very precise specification limits (0.1mm or less) defined by the end user. What makes this technology even more amazing is that all of this is now accomplished automatically, without the need for an inspection set-up expert.

Optics

Traditionally, the finish area of a container would be inspected with a top-down view. The bottle was inspected by looking at the top of the bottle from above, by different lighting methods and techniques used to highlight or suppress features of the container.

In this image of the sealing surface, the illumination is coming from the sides (cone light). This type of lighting highlights the edges of the sealing surface along with any other glass edges.

As a result, reflected light can be seen from the Wire Edge defect (if you know what you are looking for). However, without knowing more about the finish it was impossible for the inspection system to be able to distinguish between a stepped ring at the match line, versus a real Wire Edge with glass protruding upwards towards the finish. This was even more of an issue when the Wire Edge spanned the entire 360° circumference of the finish.

Rethinking an approach

Quality managers will not look for the Wire Edge defect from above but will tilt the container and change the viewing angle until they can see the defect. This behavior made it clear, in order to create a new inspection device that could reliably detect these defects, that acquisition of images at the proper angles was necessary.

Quality managers will not look for the Wire Edge defect from above but will tilt the container and change the viewing angle until they can see the defect. This behavior made it clear, in order to create a new inspection device that could reliably detect these defects, that acquisition of images at the proper angles was necessary.

The challenge to face was that people interpret the image much easier and more accurately than any vision system. Humans see the glass edge on the finish that shouldn’t be there and easily determine if it is good or bad. However, vision inspection systems need to be configured to see a feature. If the feature changes at all, the system might not be able to determine if it is good or bad.

These constraints apply to all conventional vision inspection looking for simple features like ‘edges’, ‘bright pixels’, ‘dark pixels’ or ‘shapes’ – when looking for these defects there are simply too many similar edges, straight lines and other simple features, that can affect the results.

As a software engineer, creating a perfect tool capable of analyzing this type of image with all of the features making up the image, along with all of the possible variations, was considered “impossible” with computer vision. Meaning, it could not be done.

Artificial Intelligence-Wire Edge

Today, Emhart Glass has achieved this utilizing the power of SCOUT AI. The new Finish-Wire Edge station uses one conventional top-down finish image and four additional images taken from the sides of the container to accurately and reliably detect the defect within the noise.

3D models

3D models

After the images are taken, they are analyzed and combined to build a 3D model of the container finish. (The inner neck ring area, where Wire Edge defects occur, is shown by the software as a yellow circle. The Wire Edge defect is marked red.) This 3D model is largely invariant to orientation changes, small reflections or lighting changes, guaranteeing the system’s high recognition and repeatability rates.

No complicated set-up

It also eliminates the need for complicated set-up. The SCOUT AI based Finish-Wire Edge inspection has been trained with hundreds of different container finish types, colours and sizes to make this analysis completely automatic. That means no set-up is required, apart from switching the function on or off and setting control limit.

But if there is no set up, what happens if the system is not trained to a defect? Again, the crucial part is the 3D model. The user can optionally train new good and defective containers to reject only the truly defective containers. The system will then compare the 3D model of each inspected container with the 3D models of the trained good and defective containers, and only reject the truly defective ones.

Conclusion: the latest cutting-edge artificial intelligence technology

Reliable Wire Edge defect detection has become a hard requirement for many production lines in the last few years.

The Emhart Glass Vision Finish-Wire Edge system uses the latest cutting-edge artificial intelligence technology to build a 3D model of each container finish based on multiple views of the container. The system can detect Wire Edge defects with minimal set-up and excellent reproducibility. It has been tested in production since the beginning of 2021 as well as in several customer acceptance tests. It can be purchased as an option for new Emhart Flexinspect B Generation III machines, and as an upgrade for existing Symplex chili-base inspection machines.

Ch-6312 Steinhausen – Switzerland

Tel.: +41-41-7494200 – Fax: +41-41-7494271

E-mail: webmaster@emhartglass.com

www.emhartglass.com