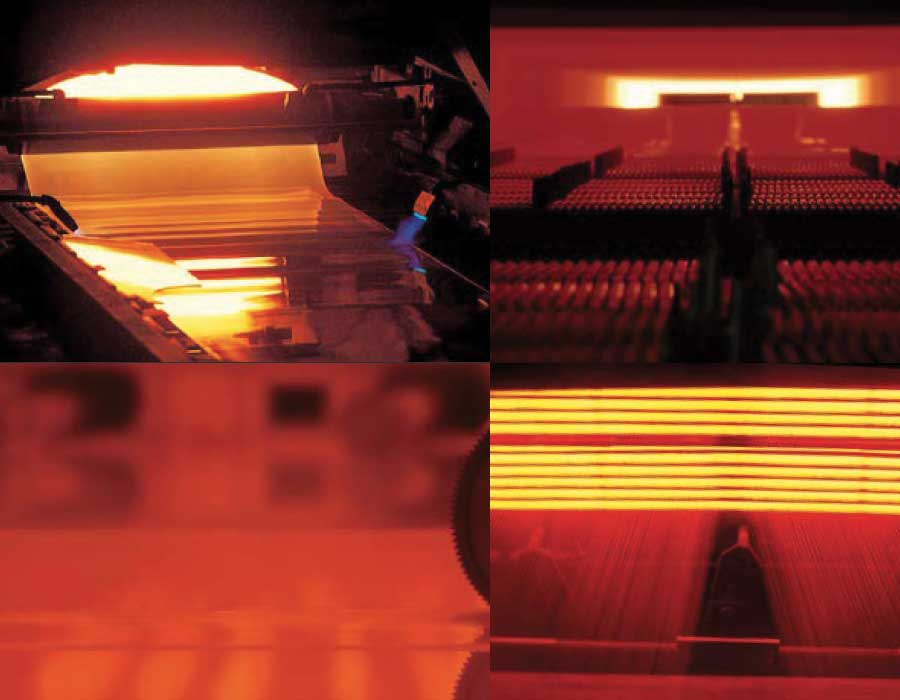

Since its establishment in 1949, Nippon Electric Glass has consistently developed and supplied new products to meet the needs of the era, accumulating and refining glass manufacturing technologies. In this article we take a look at how this company is continuing to pursue its goals, providing world-class innovative glass manufacturing technologies and products.

|  |

Special glass can be formed into a variety of shapes and infused with different properties and functions. It can be made into unique materials and products for use in diverse fields such as IT equipment, automobiles, medical care, lighting, architecture, and the energy sector. Special glass increases the speed and capacity of data communication. It makes automobiles lighter and stronger and improves fuel efficiency. It doesn’t break at high temperatures and protects against fire. It reinforces concrete and provides a solution to aging infrastructure.

COMBINING TECHNICAL KNOW-HOW WITH UNIQUE SOLUTIONS

Nippon Electric Glass (NEG) combines its accumulated technical know-how with unique solutions to deliver innovative glass products for use in industry and daily life. The company has, in fact, been developing and providing glass suitable for the times since it was established in 1949. Beginning with glass tubing for vacuum bulbs in radios, it went on to expand its product line to various areas that support society, including automotive and transportation, ICT and semiconductors, medical care, displays, lighting, energy, social infrastructure, and home appliances.

In recent years, the needs for glass have changed substantially to adapt to rapid transitions in society and the market environment. Thanks to state-of-the-art glass manufacturing technology, NEG manufactures glass products with various shapes and diverse functions to help address social needs such as reduction of environmental burden, innovation of ICT, and the advancement of medical care.

The special glass produced by NEG plays unnoticed roles in various areas, such as thin, smooth glass substrates in television displays, glass fiber in high-function plastic automobile parts, and glass for electronic devices such as smartphones. In addition, NEG glass-ceramics are used in top plates of cooking appliances and walls in train stations.

AUTOMOTIVE AND TRANSPORTATION

To accommodate stricter environmental regulations, improvement of fuel efficiency and environmental performance are urgent issues in the field of transportation. Glass fiber with a diameter just over 10µm has great mechanical strength and improves the strength, hardness, and dimensional stability of plastic and is used worldwide to reduce the weight of automobile parts and components. NEG glass is also used for in-vehicle displays and sensor-related products, while Lamion™ is gaining popularity for use in train station platform doors.

E-Glass fiber

Plastic reinforced with NEG glass fiber is used in automobile parts such as engine components to contribute to weight reduction and better fuel efficiency. Since the use of resin allows for integrated moulding of complicated parts, it helps to conserve energy in the manufacturing process.

Display-related glass

Display glass is used in smart rear-view mirrors and information displays for vehicles. The half mirrors used in rear-view mirrors function as normal mirrors and can be switched to display images from a rear-view camera. Even during bad weather or at night, clear rear-view images can be displayed.

Sensor-related glass

In-vehicle sensors are an essential part of safe and comfortable driving. NEG cover glass for image sensors, infrared absorbing filters, and band pass filters are important parts of in-vehicle sensors.

Lamion™, ultra-thin glass laminated on resin

G-Leaf™ is laminated onto one or both sides of a resin plate or film to make Lamion™. This hybrid material has both the abrasion resistance and gas barrier properties of glass and the light weight and shock resistance of resin. It is being used in train station platform doors and covers for digital signage.

ICT AND SEMICONDUCTORS

The information communication field is constantly undergoing rapid market changes and technological innovation. Glass with excellent properties, such as transmittance, hermeticity, and electrical insulation, plays an important role in optical and electronic devices that support a highly information-oriented society.

Glass substrate/cover glass

NEG offers a variety of glass substrate products which have optical and/or electrical functions, mechanical strength, and chemical durability. Applications include cover glass for image sensors and infrared absorbing filters used in sophisticated cameras, and glass for supporting semiconductor wafers used in the semiconductor manufacturing process.

Functional powder glass/glass paste

These are widely used to form insulating films, coat electronic components, and hermetically seal electronic devices such as power semiconductors. Material design can be optimized for each application. Processed products also include green sheets, glass paste, and tablets.

Glass for optical communication

By utilizing material development, precision machining, and assembly technologies required for glass manufacturing, NEG provides various products that connect high-speed optical communication networks. Products include micro prisms, micro lens arrays, micro balls, aspherical lenses, and micro capillaries.

Glass frit for laser-sealing of ceramic package

NEG developed the world’s first glass frits for laser-sealing of ceramic pack- ages that are an optimal solution to sealing glass lids and ceramic cavities. NEG glass frit for laser-sealing of ceramic package enables local laser heating, which reduces thermal damage and contributes to increased reliability and extended lifetime of electronic devices.

MEDICAL CARE

NEG has been contributing to the development and improvement of safety in the medical field by supplying glass tubing for pharmaceutical and medical use as well as radiation shielding glass. Glass tubing is used for ampoules, vials, and injection syringes. Radiation shielding glass protects health care providers from radiation exposure.

Glass tubing for pharmaceutical and medical use

BS (Clear Borosilicate Glass Tubing) has excellent chemical durability and heat and shock resistance. It is an advanced glass with a low coefficient of thermal expansion and low alkaline elution. NEG also produces BS-A (Amber Borosilicate Glass Tubing) that has both a light-shielding effect and visibility features.

Radiation shielding glass

This high-performance glass protects health care providers from radiation exposure. Its high transparency contributes to accurate diagnosis. LX Premium can be wiped with a wet cloth and has excellent shock resistance. GR Premium is a gamma-ray shielding glass suitable for positron emission tomography (PET) facilities.

DISPLAYS

Displays are essential as an interface for communication devices such as televisions, computers, digital cameras, and smartphones. With NEG highly-advanced technology, Nippon Electric Glass supports the continuing evolution of larger, higher-precision, and flexible displays.

Glass for flat panel displays (FPDs)

Alkali-free glass substrates (OA-10G and OA-11) are used for flat panel displays such as LCDs and OLED displays, since they do not affect semiconductors in the display manufacturing process. NEG glass substrate, with extremely smooth surface, is formed by the overflow process. OA-11 is easy to handle even though the glass substrate is very thin, with little deformation and gravity deflection.

G-Leaf™, ultra-thin glass

G-Leaf™ is an ultra-thin glass no more than 0.2 mm (200µm) thick that maintains the excellent functions and reliability of glass. Since it can be rolled up, it improves transport efficiency and enables roll-to-roll processing, and is regarded as a next-generation material. It contributes to energy conservation and reducing environmental burdens. G-Leaf™ is ideal for use in many areas, including displays.

Dinorex™, glass for chemical strengthening

Dinorex™ was developed as glass for chemical strengthening for use in cover glass to protect screens for smartphones and tablets. It is also being used as covers for CID (center information displays) and instrumental panels for automobiles.

LIGHTING

NEG glass is used in lighting with high luminance and high output, such as LED lighting, LD (laser diode) lighting, OLED lighting, and other lighting applications.

Lumiphous™, phosphor-glass composite

Lumiphous™ is a phosphor-glass composite that changes the wavelengths of a light source of LED and LD lighting. With less dispersion, it can express a variety of colours. Compared to resin materials, it has excellent heat, light, and water resistance, and high-power light emission.

Glass substrate with internal extraction layer (IEL) for OLED lighting

This glass can efficiently bring out light that occurs in OLED layers and substantially improves the luminance of OLED lighting.

ENERGY

NEG supplies glass fiber that reinforces wind turbine blades for wind power generation. NEG contributes to the expansion of natural energy use by providing solar mirrors used for solar thermal power generation facilities and focusses on developing ultra-thin light-weight mirrors for use in future solar power generation in space.

E-Glass Fiber

Wind power generation uses wind to generate electricity. Wind turbine blades made of glass fiber reinforced plastic (GFRP) using NEG E-Glass Fiber are light- weight and have weather resistance that can withstand strong wind, salt damage, UV light, and other factors.

Solar mirrors

Almost 100 per cent reflectance is realized by forming 100 dielectric layers on glass substrate with high light transmittance and heat resistance and a low coefficient of thermal expansion. The coatings are resistant to 300°C or more and the solar mirrors are used in photovoltaic power generation. We combined this with ultra-thin glass technology to develop mirrors for use in outer space for the Space Solar Power System (SSPS).

IMPROVING SAFETY AND COMFORT

FireLite™, fire-rated glass

With an extremely low coefficient of thermal expansion, FireLite™ can with- stand rapid temperature changes and does not break during a fire even when hosed with water. FireLite™ meets US UL* standards. FireLite Plus™ is made of layers of FireLite™ laminated together and will not shatter even when it breaks. This is the only laminated glass approved for use in fire protective facilities in Japan.

*Underwriters Laboratories

Invisible Glass™, ultra-low reflection glass

Bare glass has a luminous reflectance of approximately 4 per cent per side, however, the reflectance of Invisible Glass™ is around 0.08 per cent to 0.5 per cent per side. It minimizes light reflectance, making it ideal for use in showcases and protective picture frame covers.

ARG Fiber

With its exceptional alkali and acid resistance, ARG Fiber is widely used in construction and civil engineering areas as a reinforcing material in GRC (glass fiber reinforced concrete) and to prevent cracks in mortar and concrete. Its reinforcement effect provides the strength for complicated designs without the need to use reinforcing steel and improves installation efficiency through modularization of parts and increases the possibilities of architecture.

E-Glass Fiber

Rigid urethane resin is reinforced with E-Glass Fiber to produce plastic foam material which can be finished to create a wood texture. With excellent strength, lightness, corrosion resistance, and ease of forming, this material is used to simulate wood in railway ties and other applications.

HOME APPLIANCES – GLASS PRODUCTS FOR DAILY LIFE

Neoceram, super heat-resistant glass-ceramics

With excellent thermal shock resistance, mechanical strength, hardness, heat uniformity, and electrical properties, Neoceram is used all over the world. It is formed into plates, tubes, and pressed products, and used in cookware and wood-burning stove and fireplace windows. It can also be coated with thin heat reflective film.

StellaShine™, super heat-resistant glass-ceramics for cooking appliances

StellaShine™ has excellent thermal shock resistance and does not crack even when splashed with cold water after repeatedly being heated to 800°C. StellaShine™ is used for top plates of gas and IH cookers, and is known for its safety properties.

Nippon Electric Glass Co.

www.neg.co.jp