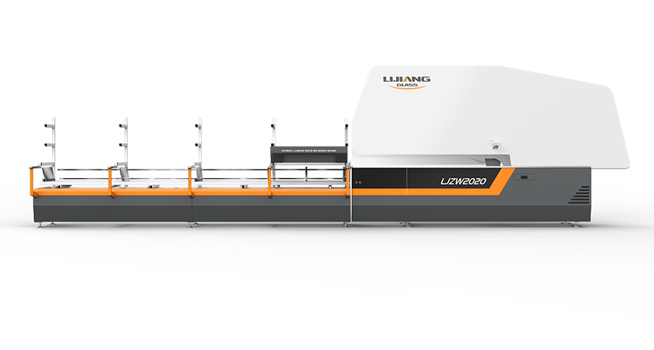

LIJIANG Glass advise the following steps for the set-up of an insulating glass aluminium strip bending machine.

- Mould adjustment

① Select appropriate mould specifications and choose different moulds according to needs;

② Install the mould and ensure that the mould is fixed and not loose;

③ Adjust the distance between the moulds to ensure that the aluminium strip will not be squeezed and deformed during bending. - Bending angle adjustment

① Adjust the bending angle as needed and adjust the corresponding degree on the adjusting wheel;

② After adjustment, conduct an actual bending test to check whether the bending angle is accurate. - Bending speed adjustment

① Select the appropriate bending speed according to the aluminium bar material and mould specifications;

② Adjust the speed on the control panel above the machine and gradually accelerate to the appropriate bending speed;

③ Carry out actual bending test to check whether the bending speed is appropriate. - Operation skills

① When placing the aluminium strip, make sure the aluminium strip is vertical to the mould to avoid deformation;

② When bending, apply pressure gradually to avoid excessive pressure at one time;

③ After the bending is completed, release the pressure on the aluminium strip bending machine and take out the folded aluminium bar.