Products that have – and are continuing to – characterise the history of the glass sector. This is how Italmole describes its work, which started at the end of the 1970s. This difficult year has created difficulties for everyone and for all industries, but has also pushed us to find new ways of communicating and – in the case of the company in this article – to provide its customers with the products they need to face these challenges.

|  |

Founded at the end of the 1970s, Italmole entered the market with its products that have characterised the history of the glass sector over the years until today.

The glass sector has made important steps forward creating new challenges for the company, which, thanks to its ability to adapt to this changing market, has always provided high quality solutions with the robustness and experience it has always put into its work.

“The secret behind this long-lasting success comes from the attention and customised technical assistance that we have always given our clients, carrying on the philosophy of technological research and great expertise in the sector,” says the owners of Italmole, who add, “Our participation in trade fairs and cooperation with machine manufacturers has introduced us to new realities by diversifying production to guarantee new quality standards.”

This is why new types of polishing wheels have been introduced, meeting the most demanding needs of clients.

NEW POLISHING WHEELS

ASTRA wheels, which have become very famous in recent times, are more silent and super-polishing, and are available only in the peripheral form. These wheels are suitable for CNC vertical machines such as Vertmax, CMS, Skillglass, as well as horizontal machines such asMaster, CMS, Bottero-Bimatech.

LOW-E is Italmole’s low-emission edge-deletion wheel, suitable for all types and brands of cutting tables, manual and automatic edger machines, and is available in all sizes.

WELL-KNOWN AND APPRECIATED PERIPHERAL WHEELS

Alongside the range of peripheral wheels, such as the highly-adaptable BD wheel with ease of use, constant quality and excellent durability, Italmole also manufacturers the BD2 engraving wheels specific for polishing engravings, available with V-shaped-, round- and off-centre profile for all types of machines.

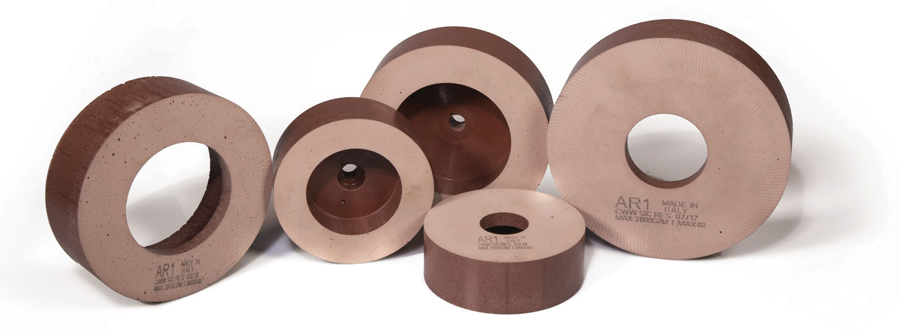

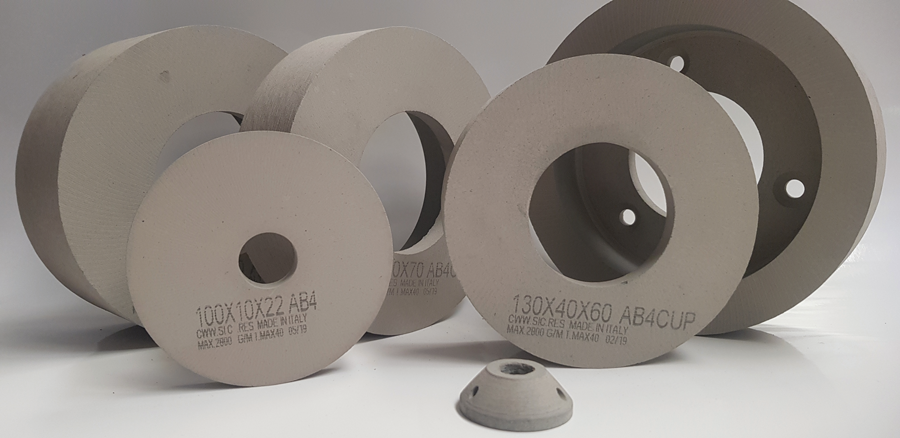

ARRISING WHEELS

Italmole arrising wheels include AB4, AR1/AR2, BLACK/RED and BDCUP.

AB4 is recommended for polishing arris on bilateral and straight machines, used after the diamond wheel, guaranteeing a brilliant and perfect polish.

The AR1 wheel is highly appreciated for Zafferani, Lattuada and Baudin machines, and is recommended for the creation of arrising without using a diamond wheel, while AR2 is recommended for use always after the diamond wheel.

BLACK is the top-of-the-range of Italmole’s arrising wheels, and is recommended for polishing of the arrising after the diamond wheel. RED, on the other hand, is used to create arrising without the diamond wheel.

Both these wheels can be equipped with any type of support, for all types of machines.

The important success of the BD peripheral wheel has led to the development of the BDCUP wheel, which has the same quality and performance also in cup shape, polishing the arris after the diamond wheel.

As with arrising wheels, where various types have been studied and manufactured for each type of use, meeting all customers’ needs, the company has also established itself worldwide in the production of cup wheels, with the X-, L- and SUPER ranges with different grits and for all types of machines. These products are available with rigid plastic support, aluminium support and special J40 support.These wheels can also be manufactured with sectors for laminated glass on request.

The importance given to customers has resulted in a great deal of stimuli and inventiveness, enabling Italmole to expand its range, offering softer or harder grinding wheels, with low noise output, suitable for prestigious, standard or for the most diverse processes.

2020 – A YEAR WHERE INDUSTRY IS BEING SERIOUSLY PUT TO THE TEST

Il 2020 is a difficult and challenging year for the whole world because of the COVID-19 emergency. Italian companies have experienced worrying moments for their work and for their employees. Like many other companies, Italmole has also tried to lessen the dramatic effects of this emergency: following government directives, the company has set up a new protocol regarding the entire working environment. Instructions have been given to all staff concerning new health and safety behaviour, providing guidance to all external visitors and couriers. A waiting area has been set up for external visitors, where temperature measurement is carried out, along with another area used for the collection and receipt of documentation and goods.

A NEW START

The beginning of September and the return to work from the traditional Italian summer holiday month, means a new start with new stimuli, hopes and expectations. The desire for collaboration and support for customers for their needs and advice is felt even more this year.

This period characterized by social distancing has alienated people, but has also brought them closer, new ways or working have been introduced to allow the continuity of activities.

Italmole will continue to work with the same philosophy and the same spirit of always adapting to changes and ensuring the continuity of the company over time.

Italmole Srl

www.italmole.com