Lattuada A-WR System is an automatic wheels pre-setting and tools wear recovery system.

The exclusive A-WR System introduces a completely automatic wheels setting management, which includes:

- Automatic pre-setting “ZERO” procedure of diamond and resin wheels, without glass in less than one minute

- Automatic recover of the polishing wheels’ wear

- Automatic positioning for the wheel’s replacement

- Jog increase/decrease of the spindle position (accuracy 0.01 mm)

- Automatic positioning on setpoint

- Automatic backlash recovery

- Automatic spindle cleaning procedure

- Wheels wear warning

- Spindle’s problems warning

- Manual unlocking for any situation

- Motorized adjustable inlet conveyor

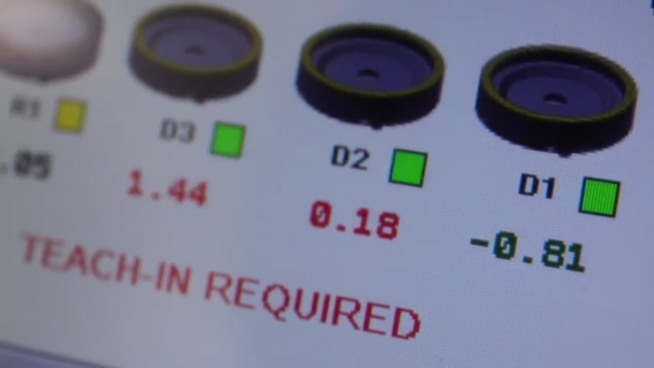

Automatic “zero” presetting of diamond and resin wheels procedure:

- At the beginning of the shift/day or whenever deemed necessary, the operator selects the “TEACH-IN” option from the touchscreen panel

- The machine stops the inlet conveyor, lowers all the spindles and then sets the diamond and the resin wheels spindles at the pre-set height with a 0,01 mm tolerance. No test glass needed

- The system also calculates the inlet conveyor belt wear for a greater accuracy

Advantages of the Lattuada A-WR System:

- Wheels setting in less than 1 minute, instead of an average 20/30 minutes manual setting

- Constant wheels setting regardless operator turnover on the machine

- Extremely simple to use, no sample glass needed

- Uniform wheels wear

- Increased spindles cleaning thanks to the spindles jog movement

- Reduced exit conveyor belt wear or damaging due to an incorrect wheels “zero” setting

- Early warning on potential maintenance issues

- Constant quality, more productivity, less maintenance… more revenue