Insulating enhancement in modern IGUs

Glazing & Energy-efficiency

Views on gas fill

Glass manufacturers of today are looking to maximize resistance to heat conductivity, and thus minimize the outflow of energy through the window. To date, this is best done by noble gas between the glass layers of an IGU. A vacuum solution between the glass panes (vacuum insulated glass) provides great temperature insulation performance, but due to price as well as technical limitations, these are seldom used in window designs of today. Air fill is an option but the use of noble gases provides superior resistance to heat conductivity in comparison with air. While air has a thermal conductivity of 0.024, argon with 0.016 is only 67 percent of that, and krypton at 0.0088, is just half the conductivity of argon (thermal conductivities).

The favoured gas is, however, argon because it is the most cost-effective noble gas to use. Compared to Argon, krypton is typically 200-300 times more expensive and xenon even more so. Estimates show that the raw material costs of producing well-sealed argon-filled IGUs, compared to air-filled ones, will go up by only 1 percent. Regardless of the choice of fill, the gas content of an IGU is generally considered to be adequate when exceeding 90 percent.

Different markets have different standards for gas content, but generally the gas content is to exceed 90 percent with a margin, although some regions have approved lower standards that match the quality performance of their local IGU-manufacturing closer. The challenge for IGU suppliers is verifying this figure by reliable measurement as solid evidence of consistent product quality (EN 1279-3: 2002; Standard test method for determining argon concentration in sealed insulating glass units using gas chromatography).

Insulating glass performance – the reason for quality control

For IGU producers, the key high quality and energy-efficient solutions lie in proper processing of advanced glass products, such as tempered, laminated and coated glass as well as skilful sealing of the gas-filled IGUs. Yearly gas fill escape due to the pressure difference between outside conditions and the gas-filled cavity is maximum 1 percent. This escape is considered normal and acceptable.

The requirement for manufacturing quality naturally includes ensuring successful and adequate gas-fill. If the processing quality is not on a high enough level, the gas escape could be much higher than this, leading to quality problems in the glass, and at worst, it could cause the collapsing of an entire glass structure.

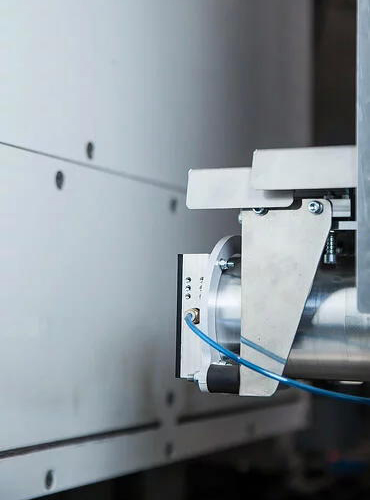

Adequate measurement

The difficulty for IGU manufacturers has been ensuring that the performance quality of the product is adequate and the inert gas-fill up to standards. Traditionally insulation gas fill was tested by taking random samples off the production line and drilling holes in the glass to measure gas fill and thus the insulation performance of the IG-unit (Argon gas fill and insulated glass units). This was a functioning, though costly method that involved breaking the glass and destroying the expensive product either on the processing line as part of manufacturing quality control or doing the same to an already installed IGU in the field.

In other words, there was no available method to measure the gas fill without tampering with the product. In the past, no method to measure gas fill in the production line as part of manufacturing on-line quality control was available. Thus, leaving out the possibility to gain gas content information from every piece produced, impairing the possibility to efficiently control the quality of the production line.

For more information on insulating glass manufacturing and quality control, see Sparklike’s web page.