The global demand for insulation fiberglass continues to grow, driven by the urgent need for energy-efficient solutions in residential, commercial, and industrial construction.

As the insulation industry moves toward decarbonisation, manufacturers are seeking materials that support longer furnace lifetime, increased use of recycled content (cullet), and reduced CO2 emissions by melting raw materials with more boosting or switching to fully electric melting furnaces.

SEFPRO is playing a critical role in this transformation with its redesigned WOOL & LEAF product lines — engineered specifically for glass wool and stone wool furnace applications.

Homogeneous design for enhanced corrosion resistance in insulation fiberglass furnace

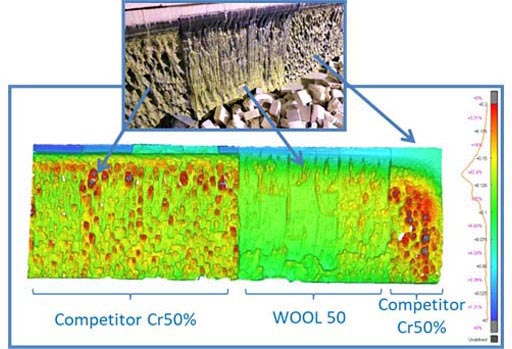

By engineering a more homogeneous distribution of chromium oxide within low-porosity grains and the surrounding matrix, SEFPRO has succeeded in developing refractories that achieve a more uniform corrosion pattern and a significantly reduced overall corrosion rate all while requiring lower levels of chromium oxide than traditional refractories.

After extensive R&D, SEFPRO’s new WOOL composition shows an improvement of approximately 10 percent in corrosion resistance compared to previous formulations. Following industrial testing, WOOL outperforms other conventional high-chromium refractories available on the market by up to 30 percent in corrosion resistance. The optimised grain design not only improves corrosion resistance but also reduces chromium sublimation near the glass line, contributing to a smoother wear profile and extended refractory life.

Driving glass industry decarbonisation through innovation

The redesigned WOOL & LEAF range demonstrates SEFPRO’s commitment to sustainable innovation. By optimising the grain density and significantly increasing the use of secondary raw materials, the WOOL & LEAF range pave the way toward the development of a circular economy and contribute meaningfully to the decarbonisation efforts of the glass industry.

In addition to their thermal and chemical resistance, these refractories also exhibit exceptional electrical resistance properties, making them suitable for hybrid furnace technologies and applications where resistance to electrical leakage is critical.

LEAF: low-energy innovation for overcoating and fast heat-up

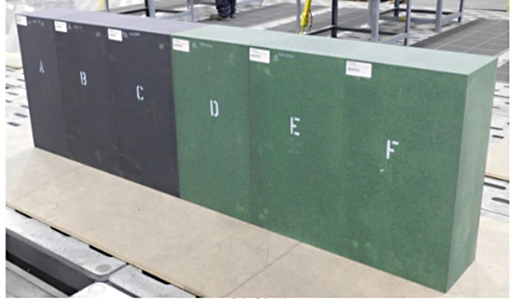

SEFPRO’s LEAF products (Low Energy Alternative Firing) take sustainability and efficiency even further. Delivered in a bisque-fired state, they complete their sintering process during application, allowing for faster furnace heat-up and superior thermal shock resistance. In addition, they maintain an equivalent corrosion resistance in use as the WOOL range and offer a smooth and stable corrosion profile.

Supporting the full glass furnace lifecycle

In addition to the WOOL & LEAF range, SEFPRO also offers a complementary portfolio of chrome based monolithic such as WOOL 50 CAST, WOOL 50 MORTAR, ERCHROM 30 CAST, and ERCHROM 30 MORTAR.

The newly developed SEFPRO CARE® Repair Hot Overcoat CHROM 50 and SEFPRO CARE® Repair Cast In Place CHROM50 respectively dedicated to hot and cold repair operations, offer dense microstructures that ensure long-lasting performances adaptable to the specific needs of customers.

Application versatility

- High-wear areas: while WOOL & LEAF may be sufficient in most areas of insulation fiber furnaces, for extreme corrosion environments like the throat area, ZIRCHROM 85 provides an extreme resistance to corrosion.

- Electrical resistivity: the ZIRCHROM HER offers high electrical resistivity combined with good thermal conductivity and good thermal shock resistance for applications such as electrode blocks.

Conclusion: performance meets purpose

SEFPRO’s latest chrome WOOL and LEAF product lines represent a new era for insulation fiberglass furnace refractories. By combining superior corrosion resistance and tailored solutions across the furnace lifecycle, SEFPRO is helping insulation fiber manufacturers to achieve higher furnace uptime, better glass quality, and reduced environmental impact.

These advancements are not just incremental—they are essential. As the insulation industry races toward its 2030 sustainability targets, SEFPRO remains a committed partner, driving real change from raw material selection through to end-of-life solutions.

Q&A

How can I extend the furnace lifespan without stopping the furnace?

Solutions for hot repair are available, such as LEAF 50 overcoating tiles or by using SEFPRO CARE® Repair Hot Overcoat Chrom50 to cast in place.

Can the new WOOL range be also used for electric furnaces?

For boosting bottom or full electric furnaces, WOOL range is well adapted with enhanced corrosion resistance for tank block and bottom paving. For electrode block applications, the ZIRCHROM HER (high electrical resistivity) provides an extremely high electrical resistance for the boosting area.

Can the WOOL range be used in the throat area?

In case of extreme corrosion, WOOL range could be sufficient. Nevertheless, in specific parts of the furnace it could be more prudent to use ZIRCHROM 85 to increase corrosion resistance limits even further.