To reduce the emissivity of its industrial process by 50 percent by 2035, Saverglass has identified a number of action levers. One of them is to use as much cullet as possible in its coloured glass.

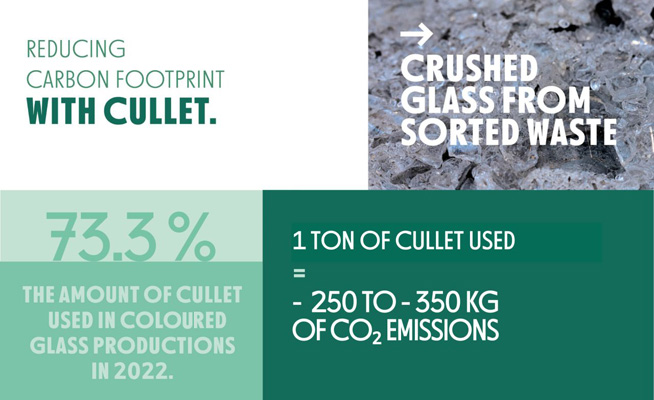

Why use cullet?

Cullet, which is simply crushed glass dust from selective sorting, has a lower and faster melting point than natural raw materials. Using cullet saves energy and reduces our greenhouse gas emissions.

A few figures

- 1 tonne of cullet avoids 250 to 350 kilograms of CO2 emissions.

- 73.3 percent is the percentage of cullet used in coloured glass since 2022.

- Furnace 23 at Saverglass’ plant in Ghlin, Belgium, uses up to 90 percent cullet in the manufacture of coloured glass.