The Italian Association of Glass Technicians (ATIV) held its annual Technical-Scientific Conference on June 12 to 13 in Parma, Italy, marking a pivotal moment for dialogue, knowledge-sharing, and collaboration across the glass industry. The event gathered over 50 participants, including engineers, researchers, industrial stakeholders, academics and technology providers, creating a dynamic environment focused on shaping the future of glass manufacturing.

The conference highlighted the central role of technical innovation, sustainability, and regulatory adaptation as drivers of transformation within the sector. This year’s edition focused particularly on the pressing needs for decarbonisation, digitalisation, and efficiency enhancement in both the hollow and flat glass segments. By offering a diverse program of high-quality presentations, ATIV reaffirmed its mission to act as a neutral and qualified platform for promoting scientific knowledge and technological advancement.

A rich and relevant program of technical contributions

The 2025 edition of the ATIV Conference provided a unique opportunity to address the multifaceted challenges and opportunities that characterise today’s glass industry. Experts from universities, companies, and institutions shared their latest findings, experiences and technological developments across a wide array of topics. Below is an overview of the main themes that emerged:

- Recycling and sustainability: The University of Padova showcased pioneering research into reusing boro-alumino-silicate pharmaceutical glass waste. Using alkali activation and microwave heating, researchers developed cold-consolidated, chemically stable materials with potential for building and insulation applications. This approach not only diverts hazardous waste from landfills but also reduces raw material consumption and CO2 emissions.

- Decarbonised raw materials: Celsian presented a comparative analysis on alternative batch materials to replace soda ash and limestone, which are major contributors to process emissions. The study highlighted viable decarbonised materials with acceptable melting behaviour, performance characteristics and economic feasibility, offering a promising path toward lower carbon glass production.

- Hydrogen combustion technologies: Stara Glass delivered a compelling update on the Horizon H2 Glass project, detailing progress in hydrogen burner development, furnace design adjustments and control system innovations. Their work demonstrates the feasibility of hydrogen-powered furnaces and underlines the need for automation to handle hydrogen’s specific combustion properties.

- Electrification and power management: Schneider Electric addressed the transition to electric melting, exploring how advanced power control systems, quality management tools, and digital twins can enhance furnace reliability, safety and energy optimisation. They also illustrated methods for predicting electrode wear and managing electric load with greater precision.

- Refractory innovations for clean melting: RHI Magnesita provided insight into how refractory linings must evolve to withstand harsher chemical environments and higher thermal loads associated with hybrid and electric furnaces. Solutions included corrosion-resistant compositions and optimised shapes for regenerators to maintain thermal performance over time.

- Advanced glass applications: Politecnico di Torino discussed three decades of innovation in glass and glass-ceramic joining and coating technologies. Their work integrates advanced testing and design of interfaces for high-performance assemblies, providing valuable tools for multiple industrial applications.

- Energy integration and techno-economic models: The University of Pisa offered a model-based evaluation of hybrid furnace configurations powered by renewable energy sources and hydrogen. Their analysis demonstrated how smart integration can help balance energy costs, emissions, and system autonomy.

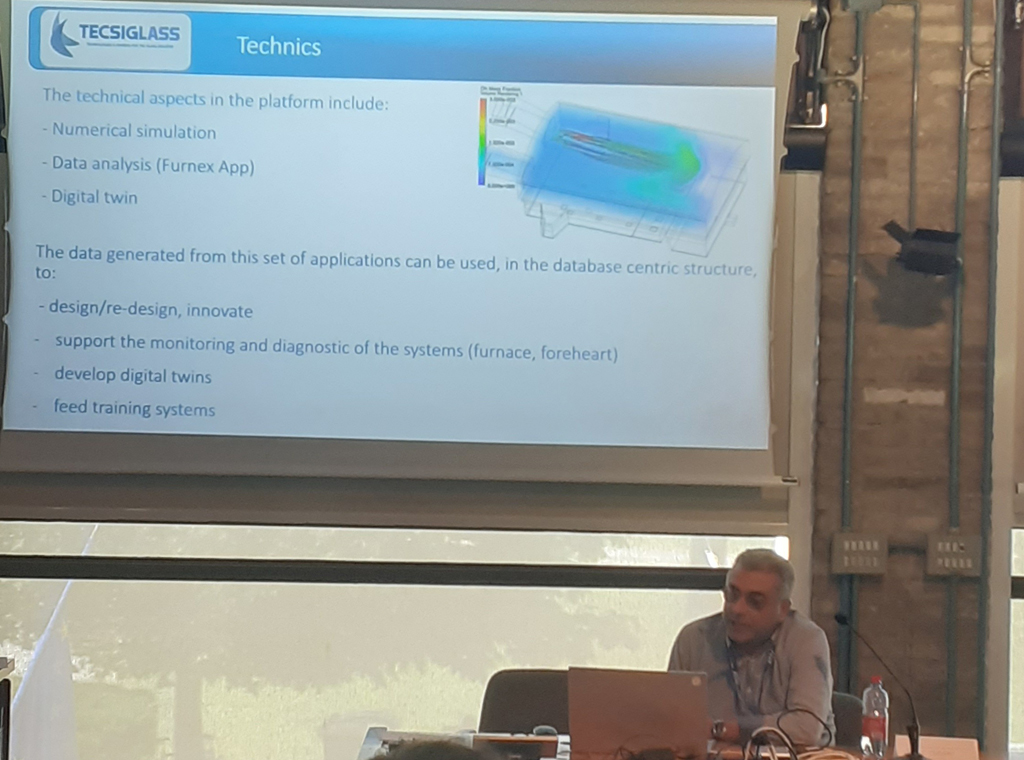

- Digitalisation and AI for process optimisation: Tecsiglass, IRIS Inspection Machines, Glass Service and Xpar Vision highlighted how artificial intelligence, real-time monitoring and virtual environments are reshaping process management. Solutions ranged from predictive maintenance to defect recognition and augmented reality training, demonstrating the power of data-driven manufacturing.

- Smart manufacturing and process automation: Heye International presented technologies for advanced thickness control and automated inspection systems. Their Smart Plant framework combines real-time data integration, process intelligence and machine learning to reduce energy consumption and optimise production.

- Electrification at scale: Fives presented the Verallia Cognac all-electric furnace – currently the largest in the European container glass sector. The presentation addressed the challenges of scaling electric melting, such as power delivery, geometry operatisation and heat distribution, while showcasing excellent performance in emissions reduction and glass quality.

Italian innovation in action

The conference also served as a showcase for excellence in Italian industrial innovation:

- OCMI presented a high-speed production line for borosilicate vials, emphasising modular design, servo-driven components and automated visual inspection for the pharmaceutical sector.

- Bormioli Luigi introduced three ambitious projects – PRIMUS, VITRUM and MAGNUS – that explore hybrid melting, forehearth heat recovery, high PCR usage and CO2 monitoring tools, all aimed at drastically reducing emissions while maintaining premium quality.

- Tecnosens shared advances in collaborative robotics for quality control, automating residual stress and thickness measurements both in-line and in laboratories. Their flexible, Industry 5.0-ready systems enhance precision, traceability and safety in the production process.

International participation reinforces ATIV’s mission

Global industry leaders added further value to the event with high-level contributions:

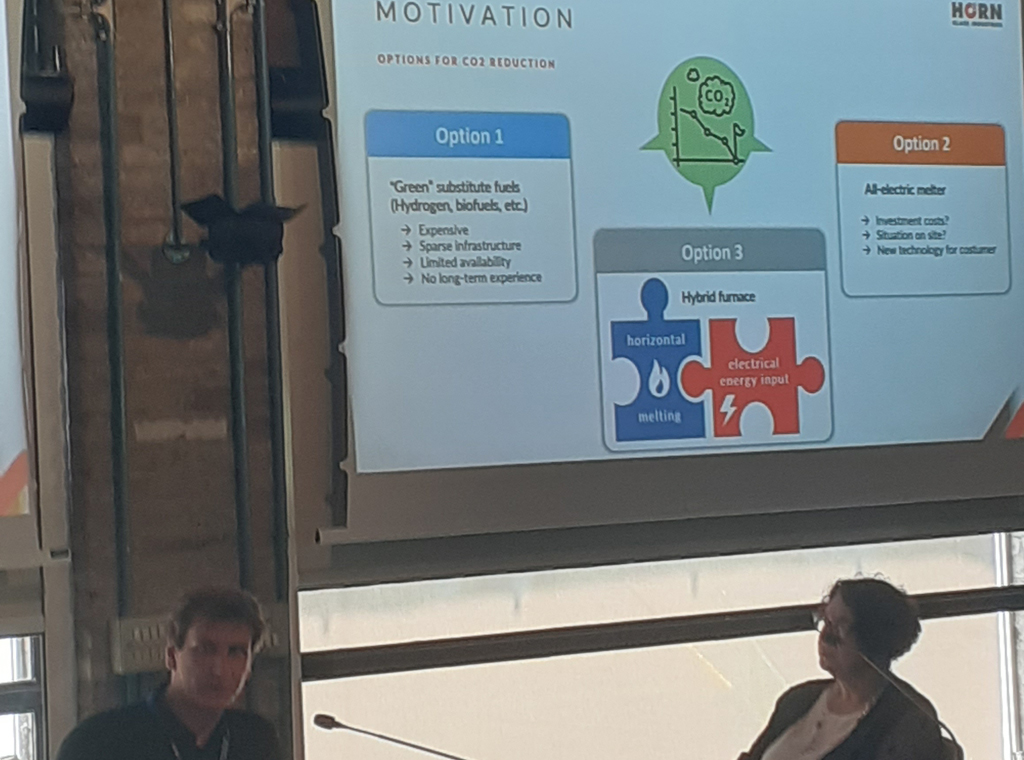

- Horn Glass Industries shared strategies for hybrid melting and transitioning from fossil fuels.

- SORG presented 100 percent electric glass conditioning solutions for complete decarbonisation.

- BDF Industries introduced innovations in feeder flow technology and combustion monitoring.

The involvement of all these players reinforced the global relevance of the Italian market and highlighted the importance of events like this in supporting cross-border collaboration and knowledge sharing.

A Constructive reflection on sector engagement

ATIV strongly believes that active engagement between glass producers and technological partners in such initiatives is crucial to support informed decision-making, innovation adoption, and collective growth.

“We see these events not only as opportunities to showcase research, but also as shared platforms to build a future-ready industry,” the ATIV Executive Board stated. “We remain confident that stronger collaboration between manufacturing and technical communities will emerge in the near future.”

Looking ahead: collaboration, knowledge and progress

ATIV reaffirms its commitment to supporting the glass industry in its journey toward greater sustainability, efficiency, and innovation. By organising technical conferences, encouraging academic-industrial partnerships and facilitating knowledge transfer, the Association continues to act as a catalyst for positive change.

The last Parma event underscored the importance of dialogue and shared vision in facing a rapidly evolving industrial landscape. ATIV invites all stakeholders to actively participate in future events and projects, reinforcing the conviction that collaboration is the key to progress.