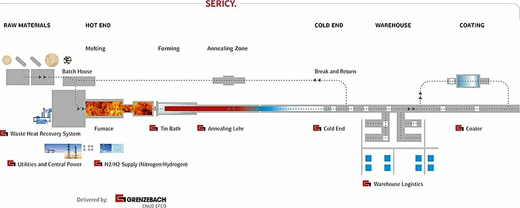

For decades, the name CNUD EFCO GFT has stood for excellent products and process know-how in tin bath, annealing lehr and utilities in float glass production. In November 2019, the Grenzebach Group took over the company, marking the beginning of an extensive integration process that has allowed numerous synergies and complements Grenzebach’s already comprehensive range of services. Since then, Grenzebach has offered its customers all the fundamentals of the glass production process – from tin bath to cold end – from a single source, right through to the transportation of the glass sheets to the warehouse.

An integration that makes everything easier

The next step on this path took place on January 1, 2022, with the full integration of the glass business into the Grenzebach Group, utilizing all of its tools and processes. Grenzebach and CNUD EFCO GFT will finally be “one family,” and customers will have only one contractual partner, Grenzebach – a clear, consistent solution that makes everything easier.

This next step is also associated with the renaming of the location in Iași, Romania. The current company name, Cnud Efco Operations, will be changed to Grenzebach Romania S.R.L. In addition, a capacity expansion is being planned at the site in Iași. A new production hall will be built in 2022.

Egbert Wenninger, CCO of the Grenzebach Group, emphasized that customers can continue to rely on the performance they are used to. “The scope of services and the proven expertise will not change; the contact persons will also remain the same,” he said. The only new features as of 2022 will be the organization structure, the company name, and the e-mail addresses. This does not affect projects that are currently in progress; from now on, all new orders will be managed under the company name Grenzebach Maschinenbau GmbH, located in Hamlar, close to Augsburg, Germany.

More synergies, less effort for customers

The successful, ever closer integration of CNUD EFCO GFT into the Grenzebach Group gives customers several substantial advantages: in view of the increasing complexity of float glass production lines, solutions from a “one-stop shop” are more economical and easier to calculate. They also provide more security in every respect over solutions from different suppliers that must be combined.

Robert Lamy, CSO of Grenzebach Belgium, said, “The joint development and planning of integrated production lines enable glass manufacturers to implement projects smoothly, with significantly reduced coordination needs and overall costs.”