In an era where contemporary architectural aesthetics are deeply integrated with the concepts of sustainable development, the performance of glass curtain walls, as the “skin” of modern buildings, directly relates to the building’s energy consumption, comfort, safety and aesthetic value. To meet increasingly stringent energy efficiency standards, traditional curtain wall glass often falls into the trap of increasing thickness and weight.

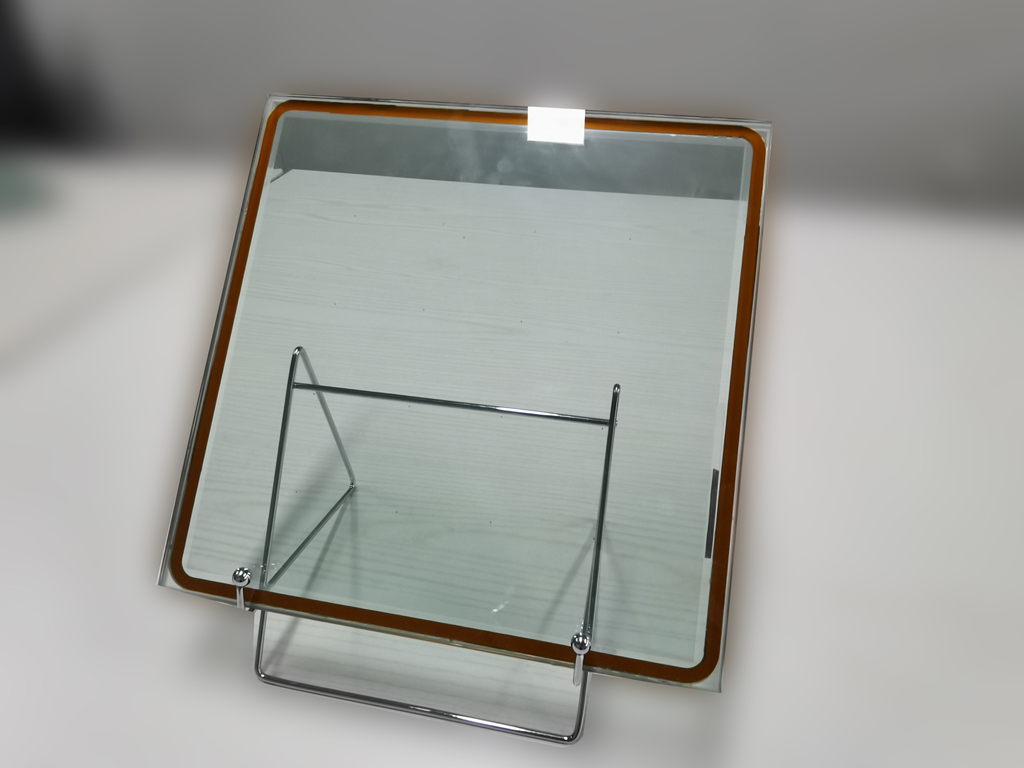

This continued until the emergence of an innovative material: Vacuum Insulated Glass Laminated(PVB). With its superior thermal insulation, slim structure and enhanced safety, it is poised to redefine the future of the glass curtain wall industry. The technical breakthroughs by Luoyang LandVac Ti-VIG have further paved the way for its large-scale, safe application.

I. The traditional dilemma: The trade-off between energy efficiency and weight

For a long time, building energy efficiency has been a core challenge in curtain wall design. The key metric for measuring a material’s thermal insulation performance, the U-value (heat transfer coefficient), is better the lower it is. To achieve a very low U-value for curtain wall glass, traditional technical approaches had to adopt extremely complex structures.

The most common solution is the “four panes, two cavities” or even “five panes, three cavities” glass configuration (with an outer PVB laminate layer to meet safety requirements). While effective, this solution comes at a significant cost: the total glass thickness easily exceeds 50 millimetres, and the overall weight is substantial. Designers are forced to balance aesthetics, energy efficiency and structural safety painstakingly.

II. A game-changer: the three core advantages of Vacuum Insulated Glass Laminated (PVB)

The advent of Vacuum Insulated Glass Laminated (PVB) perfectly solves the aforementioned dilemmas, with its advantages concentrated in three key areas:

- Exceptional thermal insulation, with a U-value as low as 0.4 W/(m2·K)

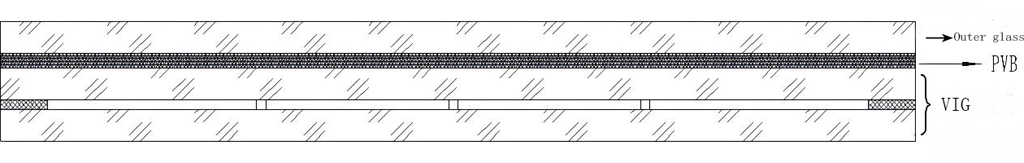

The secret to its ultra-low U-value lies in the core ‘vacuum cavity.’ The vacuum environment eliminates heat transfer through air convection and conduction, greatly enhancing thermal insulation performance. When combined with the PVB laminate and Low-E coating technology, it forms a highly efficient thermal barrier. - Extreme thinness and significant weight reduction

Compared to the bulky 50 millimetre and up profile of traditional solutions, the total thickness of Vacuum Insulated Glass Laminated (PVB) can be controlled to an astonishing 19 millimetres. This sharp reduction in thickness leads to a significant reduction in weight. Not only does this lower the transportation and installation costs of the glass itself, but more importantly, it greatly reduces the load on the building’s main structure and the curtain wall support system. - Enhanced safety and structural adaptability

The weight reduction directly translates to a lower requirement for the curtain wall structure’s strength. Lighter glass means the frame can be designed to be more slender, connectors can be more refined, and the entire support system has a higher safety margin. At the same time, the PVB film used in the composite ensures that if the glass shatters from an impact, the fragments will firmly adhere to the film, effectively preventing them from falling and causing injury, thus providing both impact and fall protection.

III. Technical cornerstone: LandVac overcomes industry challenges, ensuring curtain wall safety

Curtain walls require the use of PVB film for the interlayer. The traditional process for PVB lamination uses a pressure of over a dozen atmospheres for bonding. However, due to its structure, vacuum glass cannot withstand such high pressure. Therefore, the lamination of vacuum glass with PVB film was a technical challenge that the industry had long failed to perfectly solve.

After years of exploration and testing, Luoyang LandVac Ti-VIG successfully solved the industry’s problem of laminating vacuum glass with PVB film. The core of their solution is a special autoclave process that achieves perfect, all-around, void-free bonding of vacuum glass and PVB film under high temperature and pressure.

IV. Application prospects: ushering in a new architectural future

The maturity of Vacuum Insulated Glass Laminated (PVB) provides strong material support for the development of green buildings, ultra-low energy buildings, and passive houses. It ensures that large, transparent glass curtain walls no longer act as “energy black holes” for a building but become highlights of energy efficiency. Whether for newly constructed landmark commercial towers or for existing building glass renovation projects aimed at improving energy efficiency, it offers a reliable solution.

In summary, Vacuum Insulated Glass Laminated(PVB) is not merely a material upgrade; it is a liberation of design concepts. It breaks the traditional paradox that energy efficiency, safety and thinness cannot be simultaneously achieved. With its groundbreaking performance advantages, it is rapidly pushing the glass curtain wall industry toward a more energy-efficient, safer, lighter and more beautiful future.