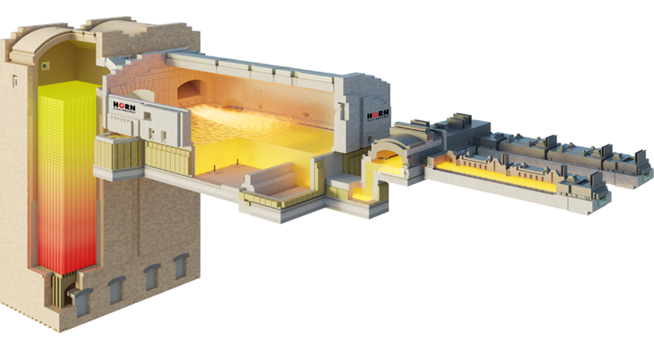

Stoelzle Glass Group has appointed HORN Glass Industries for the cold repair of its furnace 1. The project includes replacing an existing furnace with a new 200 tonnes per day end fired furnace at Stoelzle’s Heřmanova Huť plant in the Czech Republic. The 70 square metre end fired furnace is designed to produce container glass products in amber and will run on natural gas.

To support both the melting process and the refining of the glass, several additional HORN e-Fusion Power Boosting Systems will be installed in the bottom of the melting tank. Proven HORN technology will help to reduce carbon emissions while maintaining high-quality glass production. This is another important step for Stoelzle towards producing glass containers with lower CO2 emissions.

The furnace will be equipped with latest glass level measuring system HORN HRD-BEAM, measurement and control technology, combustion system as well as further state-of-the-art equipment. Engineering of the refractories, installation of the steel construction, equipment installation and commissioning will all be carried out under the constant supervision of HORN.

The project will be managed and executed by HORN Glass Industries with additional support provided by its subsidiary HORN Moravia.

The furnace is to be repaired under HORN’s supervision in Q1 2026.