BOLD Laser Automation, a developer of advanced laser processing and metrology systems, has launched a new line of certified calibration thickness gauges engineered for calibration of high-accuracy Confocal Differential Measurement Systems. Standard and application-specific designs ensure NIST traceable thickness measurements in film, foil, thin glass and technical fabrics. Designed specifically for integration with Keyence Dual Confocal Laser (CL) displacement sensor configurations, the calibration gauges enable precise non-contact thickness measurement across a range of inline inspection and quality assurance environments.

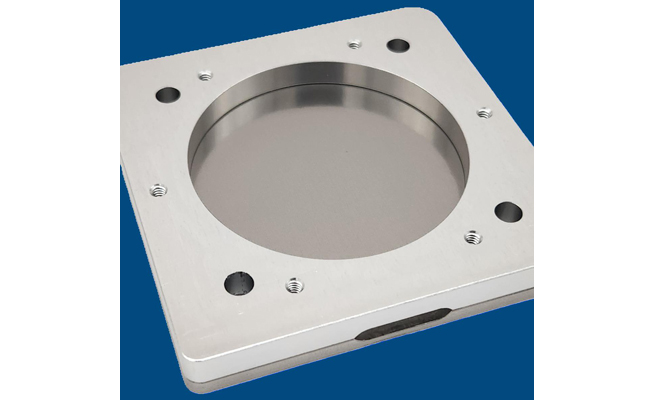

Developed for integration into discrete filtration and roll-to-roll (R2R) manufacturing environments, the calibration gauges support fast, repeatable calibration routines across a variety of product widths and materials. Each gauge is manufactured to stringent tolerances, with foil and block thicknesses from 0.010 mm to 2.000+ mm using a variety of precision-certified materials that include molybdenum, stainless steel and titanium. The gauges are available in both standard configurations for common film and foil thicknesses, as well as custom options for specialised production requirements.

“Our calibration gauges provide the backbone for quick and reliable, real-time metrology in demanding applications,” said Todd Lizotte, President & CEO of BOLD Laser Automation. “When paired with the precision and speed of Keyence’s CL-series confocal laser displacement sensors, our system ensures that manufacturers can maintain tight control over product thickness and material uniformity—critical metrics for food industry packaging, medical device, aerospace, and advanced packaging sectors.”

Key features of the new calibration gauge product line include:

- NIST-Traceable Thickness Certification for reliable calibration standards

- Compatible Mounting Designs for Inline Sensor Integration across inspection platforms

- Industrial-Grade Surface Durability to withstand high-repetition use

- Custom Engraving and Calibration Targets for automated alignment and validation

To access the latest book from Todd E. Lizotte, CEO and co-founder of GOLD Laser Automation, see Laser Beam Shaping Applications, Second Edition.