Page 39 - Glass Machinery Plants & Accessories no. 2-2020

P. 39

glass thermocouples

are still required.

VIRTUAL NIR

TEMPERATURE

INFORMATION

Operating tem-

peratures can be

monitored, but also

other aspects of

furnace operations

such as bubbling

can be observed as

well.

The virtual NIR

temperature infor-

mation correlates

well with furnace

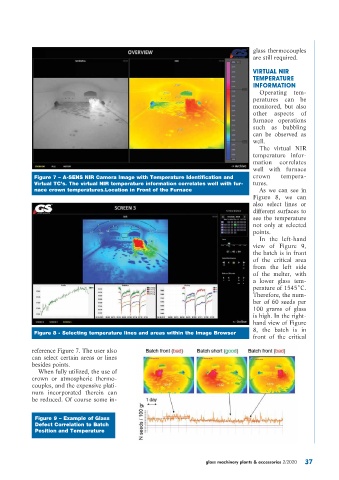

Figure 7 – A-SENS NIR Camera Image with Temperature Identification and crown tempera-

Virtual TC’s. The virtual NIR temperature information correlates well with fur- tures.

nace crown temperatures.Location in Front of the Furnace As we can see in

Figure 8, we can

also select lines or

different surfaces to

see the temperature

not only at selected

points.

In the left-hand

view of Figure 9,

the batch is in front

of the critical area

from the left side

of the melter, with

a lower glass tem-

perature of 1545˚C.

Therefore, the num-

ber of 60 seeds per

100 grams of glass

is high. In the right-

hand view of Figure

8, the batch is in

Figure 8 - Selecting temperature lines and areas within the Image Browser

front of the critical

reference Figure 7. The user also

can select certain areas or lines

besides points.

When fully utilized, the use of

crown or atmospheric thermo-

couples, and the expensive plati-

num incorporated therein can

be reduced. Of course some in-

Figure 9 – Example of Glass

Defect Correlation to Batch

Position and Temperature

glass machinery plants & accessories 2/2020 37