Page 37 - Glass Machinery Plants & Accessories no. 2-2020

P. 37

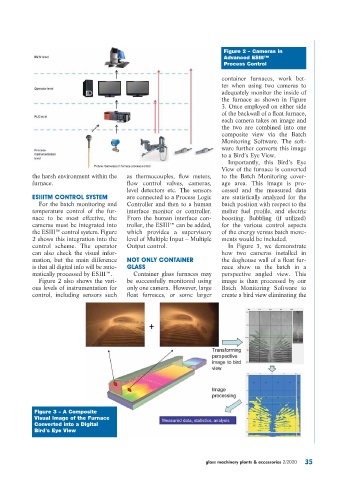

Figure 2 – Cameras in

Advanced ESIII™

Process Control

container furnaces, work bet-

ter when using two cameras to

adequately monitor the inside of

the furnace as shown in Figure

3. Once employed on either side

of the backwall of a float furnace,

each camera takes an image and

the two are combined into one

composite view via the Batch

Monitoring Software. The soft-

ware further converts this image

to a Bird’s Eye View.

Importantly, this Bird’s Eye

View of the furnace is converted

the harsh environment within the as thermocouples, flow meters, to the Batch Monitoring cover-

furnace. flow control valves, cameras, age area. This image is pro-

level detectors etc. The sensors cessed and the measured data

are connected to a Process Logic are statistically analyzed for the

ESIIITM CONTROL SYSTEM

For the batch monitoring and Controller and then to a human batch position with respect to the

temperature control of the fur- interface monitor or controller. melter fuel profile, and electric

nace to be most effective, the From the human interface con- boosting. Bubbling (if utilized)

cameras must be integrated into troller, the ESIII™ can be added, for the various control aspects

the ESIII™ control system. Figure which provides a supervisory of the energy versus batch move-

2 shows this integration into the level of Multiple Input – Multiple ments would be included.

control scheme. The operator Output control. In Figure 3, we demonstrate

can also check the visual infor- how two cameras installed in

mation, but the main difference NOT ONLY CONTAINER the doghouse wall of a float fur-

is that all digital info will be auto- GLASS nace show us the batch in a

matically processed by ESIII™. Container glass furnaces may perspective angled view. This

Figure 2 also shows the vari- be successfully monitored using image is than processed by our

ous levels of instrumentation for only one camera. However, large Batch Monitoring Software to

control, including sensors such float furnaces, or some larger create a bird view eliminating the

Figure 3 – A Composite

Visual Image of the Furnace

Converted into a Digital

Bird’s Eye View

glass machinery plants & accessories 2/2020 35