Page 38 - Glass Machinery Plants & Accessories no. 2-2020

P. 38

AUTOMATION AND CONTROL

Automation and control

perature clearly drops when the

batch moves to the front of the

furnace. Hence, the measured

batch coverage area is used as

additional input into the ESIII™

furnace temperature control.

During the next step, ESIII™

controls the batch coverage by

Figure 4 – A Visual Camera Image Converted to Batch Pile automatic adjustment of the

Locations within the Furnace Melter

batch charging direction(s).

Crown temperatures are

identified by the A-SENS NIR

Camera as shown in Figure 6.

This new camera provides two

video streams, including the reg-

ular vision information plus a cal-

ibrated temperature using near

infrared wavelength in parallel.

Temperature measurements

can be made at virtually any

point within the view of the cam-

era, although certain selected

temperatures are mostly utilized.

The number of pixels within the

Figure 5 – Location for a Critical Batch Free

Location in Front of the Furnace cameras view can determine the

number of temperatures that can

be monitored. There are sev-

perspective effects. Finally, this be batch free, see Figure 5. Batch eral temperature areas noted,

image is digitized allowing us to coverage in front of the furnace including the port neck area,

extract absolute batch coverage in this area has been directly the crown, and the glass surface,

information that can be further related to an increase in the

processed by the Expert System number of glass defects. Again,

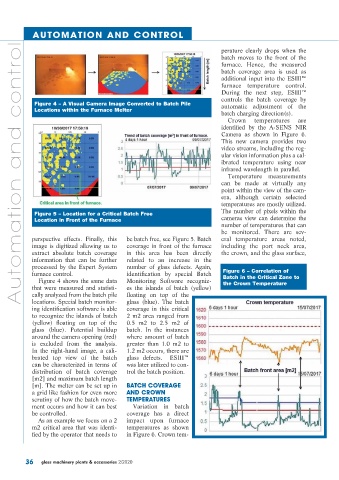

furnace control. identification by special Batch Figure 6 – Correlation of

Figure 4 shows the same data Monitoring Software recogniz- Batch in the Critical Zone to

that were measured and statisti- es the islands of batch (yellow) the Crown Temperature

cally analyzed from the batch pile floating on top of the

locations. Special batch monitor- glass (blue). The batch

ing identification software is able coverage in this critical

to recognize the islands of batch 2 m2 area ranged from

(yellow) floating on top of the 0.5 m2 to 2.5 m2 of

glass (blue). Potential buildup batch. In the instances

around the camera opening (red) where amount of batch

is excluded from the analysis. greater than 1.0 m2 to

In the right-hand image, a cali- 1.2 m2 occurs, there are

brated top view of the batch glass defects. ESIII™

can be characterized in terms of was later utilized to con-

distribution of batch coverage trol the batch position.

[m2] and maximum batch length

[m]. The melter can be set up in BATCH COVERAGE

a grid like fashion for even more AND CROWN

scrutiny of how the batch move- TEMPERATURES

ment occurs and how it can best Variation in batch

be controlled. coverage has a direct

As an example we focus on a 2 impact upon furnace

m2 critical area that was identi- temperatures as shown

fied by the operator that needs to in Figure 6. Crown tem-

36 glass machinery plants & accessories 2/2020