Glass Technology Services (GTS) has been awarded a contract under the United Kingdom Atomic Energy Authority’s (UKAEA) Fusion Industry Programme, as part of a national GBP 8.1 million investment supporting next-generation shielding and fuel-cycle technologies for future fusion power plants.

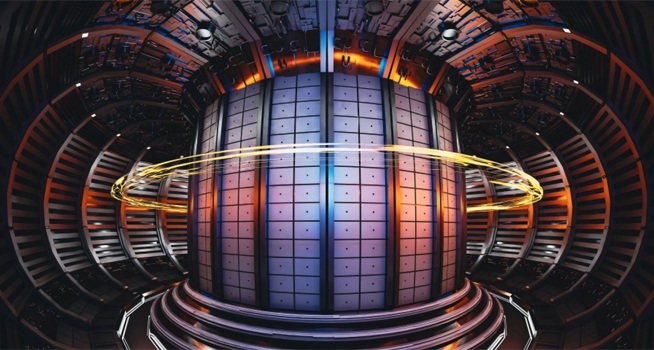

Working in partnership with Sheffield Hallam University, GTS is leading the project “Glass and glass-ceramics for fusion reactor shielding applications.” The project investigates the potential of glass and glass-ceramic materials to serve as economical and sustainable radiation shielding solutions within fusion energy systems and associated plant environments.

The project is taking an economics‑ and sustainability‑driven approach to identify materials that are both low‑cost and environmentally responsible, while still meeting the stringent performance requirements of nuclear fusion.

By exploring alternatives that are holistically competitive with traditional shielding materials, such as lead, concrete, and specialist metal alloys, the team aims to deliver solutions that combine high physical performance with lower costs, reduced environmental impact, and simpler end‑of‑life management. This work aligns closely with the UK’s commitment to sustainable innovation and the advancement of clean‑energy technologies.

As part of the programme, GTS and Sheffield Hallam University is undertaking a comprehensive programme of work including:

- Identification and modelling of high-performance glass and glass-ceramic materials.

- Simulations to evaluate radiation attenuation behaviour.

- Laboratory scale melting trials to validate material feasibility and performance‑scale melting trials to validate material feasibility and performance

- Assessment of commercial manufacturing routes, including integration of secondary raw materials.

- Lifecycle and environmental impact analysis to ensure long-term sustainability and end-of-life viability.

Dr Owen McGann, Principal technologist and Innovation development lead, said “Glass and glass-ceramic technologies offer a unique combination of compositional flexibility, manufacturability and radiation‑shielding capability.

“This project gives us the opportunity to demonstrate how these materials can deliver sustainable, economical, high-performance shielding solutions which support the UK’s long-term fusion energy ambitions.”