Many manufacturers have found Sparklike to be an essential part of their IGU quality strategy. Real customer cases demonstrate that measuring invisible issues allows companies to optimise gas filling processes, verify seal integrity and maintain consistent IGU performance.

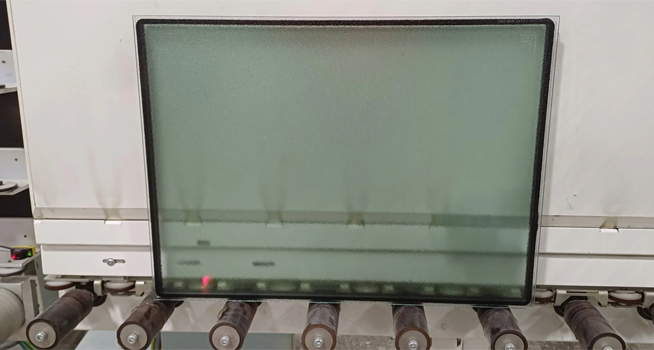

Visible IGU defects: what automated systems catch

Visual inspection systems are excellent at detecting surface-level and assembly-related issues. These include:

- Scratches, dirt and inclusions

Contaminants or surface damage introduced during handling, cutting, washing, or assembly. - Edge defects and chipping

Produced during cutting or grinding. These issues can reduce durability and increase breakage risk. - Optical distortions and roller wave

Typical in tempered glass, causing uneven reflections. Systems from Viprotron or Softsolution detect and quantify these defects. - Anisotropy

A visual effect from stress patterns created during tempering. Now widely monitored to ensure consistent visual quality. - Misalignment or spacer defects

Visible mechanical issues that may lead to air leakage, stress, or premature failure of the unit.

These systems ensure an IGU looks correct before it leaves the production line. But appearance is only one part of quality and not the only part that determines insulation performance.

CRITICAL DEFECTS NO VISUAL SYSTEM CAN DETECT

Incorrect gas fill rates: invisible but immediately impactful

Even a flawless-looking IGU can be significantly under-filled with argon or krypton.

Many manufacturers first discovered this hidden defect after using Sparklike devices to check their production. Some found:

- IGUs filled to only 50–60 percent of target levels

- variations between operators and shifts

- differences in triple-glazed cavities

- temperature-related filling inconsistencies

Manufacturers used Sparklike devices to check their gas press performance. This helped them change their filling parameters. As a result, they achieved more consistent U-values and reduced failed energy tests.

Gas leakage over time: environmental stress creates invisible failures

A unit can pass all factory checks yet lose gas months later. In a test, a Sparklike customer checked how insulating glass units keep argon gas. They also tested how these units react to changes in latitude.

Seal failures: hidden weaknesses that are hard to see

Even when an insulating glass seal looks intact, it may not be performing as intended. Visual inspection cannot show whether the hermetic seal is still maintaining the correct gas concentration inside the IGU.

Sparklike devices measure the noble gas content (such as argon or krypton) as a percentage. By taking successive measurements from the same unit over time, quality teams can track how the gas concentration changes.