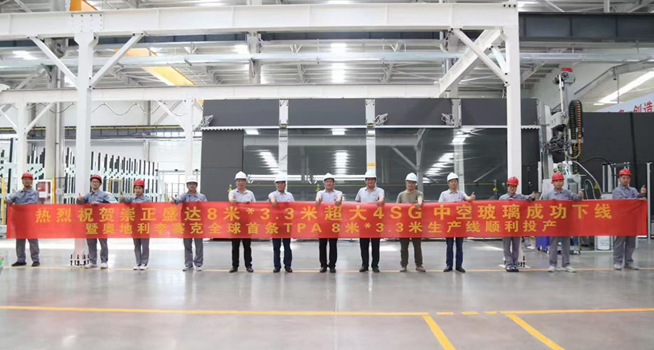

By installing the world’s first 8 by 3.3 metre insulating glass line with thermoplastic spacers (TPA) from LiSEC, Chongzheng Shengda Glass is taking an important step in developing its production technology further. The project does not just mark a world’s first in producing large-format TPS insulating glass but also underlines the leading technological role that both companies are taking in implementing more innovative, efficient and sustainable production solutions.

Chongzheng Shengda Glass, part of the Shandong Chongzheng Group, is one of the leading manufacturers of energy-efficient functional glass in China. The company operates the most modern production systems in the high-tech industrial park in Zibo and focusses on high quality 4SG and low-E glass products for architecture, façades and structural engineering. By deciding for the LiSEC 8 by 3.3 metre TPA line, the company is continuing its consistent strategy of using technology as a lever for quality and sustainability.

The LiSEC TPA system (Thermoplastic Spacer Application) replaces conventional frame production with fully-automatic, direct application of the thermoplastic spacer material onto the glass sheet. The material is fed from a drum, heated up, applied precisely and then hermetically sealed at the corners using a compression system.

Clear advantages of the TPA technology:

- Seamless production process: No bending or installing frames – therefore, shorter cycle times and low risk of errors.

- Highest precision: Automatic edge sealing without visible joints or height deviations.

- Maximum flexibility: Seamless change between different insulating glass sizes and spacer widths without changeover times.

- Permanent sealing: Chemically stable connection between the glass, TPA material and the sealant ensures extreme durability of the insulating glass unit.

- Energy efficiency: Reduced material consumption, optimised drying cycles and up to 30 percent less energy consumption compared to conventional production methods.

The partnership between Chongzheng Shengda Glass and LiSEC goes back as far as 1998. Even the very first LiSEC insulating glass line and cutting system proved itself over two decades. The trust in quality, project management and technical competence was therefore decisive for implementing the new 8 by 3.3 metre TPA line, a system that is unique in the world in these dimensions.