In the past two years, Glaston has closed several automotive glass processing deals in key global markets, including Japan, China, Croatia, South Africa, the United States and Brazil and demand for Glaston’s automotive technologies continues.

In the early 2000s, demand shifted toward larger glass sizes to provide drivers with better visibility and a more streamlined vehicle design.

This was followed by the emergence of increasingly more complex glass geometries, exemplified by models such as the Mini, where distinctive styling created new challenges for glass shaping and processing.

Most recently, the rapid development of electric and autonomous vehicles has further reshaped requirements. Modern vehicles now incorporate many advanced driver assistance systems (ADAS), cameras and sensors that must be protected behind glass without compromising optical performance.

These trends call for flawless optics and consistent quality throughout the production process. Today’s equipment must be capable of supporting these requirements at every stage, from pre-processing to laminating and tempering.

Windshield glass always requires lamination to meet safety and performance standards. Sidelites require both tempering and lamination to enhance passenger comfort by reducing noise and increasing safety. Backlights, too, are becoming more complex, requiring a process that ensures greater visibility and functional reliability.

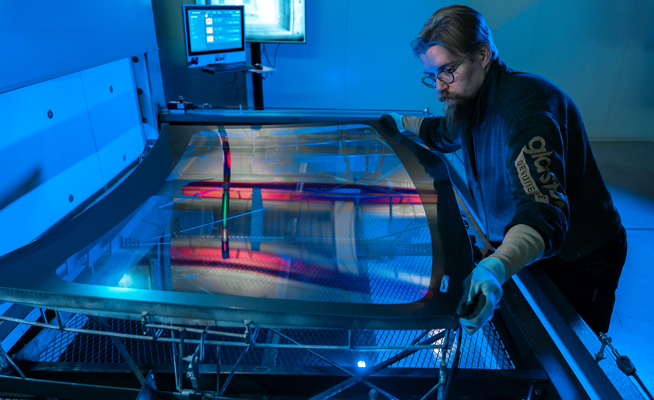

With deep expertise across all key automotive glass production processes, from pre-processing through laminating and tempering, Glaston serves as a single partner for end-to-end production. The company offers the market a comprehensive family of processing lines, including MATRIX, MATRIX EVO and CHAMP EVO. These solutions enable processors to efficiently and reliably produce more demanding, more challenging glass.

MATRIX and MATRIX EVO are designed for single-model or mixed production of wind-shields and sunroofs, handling the most complicated shapes with superb bending control. Active convection preheating ensures uniform temperature for superior optical quality and high yield, while minimising energy use and operational costs.

CHAMP EVO delivers highly efficient and precise cutting, breaking and grinding over short cycle times with high repetition accuracy. Its automated, flexible layout also enables fast changeovers and supports advanced tempering needs.

Glaston’s offerings for the automotive industry are unique in many ways. Its finely tuned wind-shield production technology, for example, reliably delivers unsurpassed yields of up to 99.5 percent, enabling processors to meet the highest customer requirements.