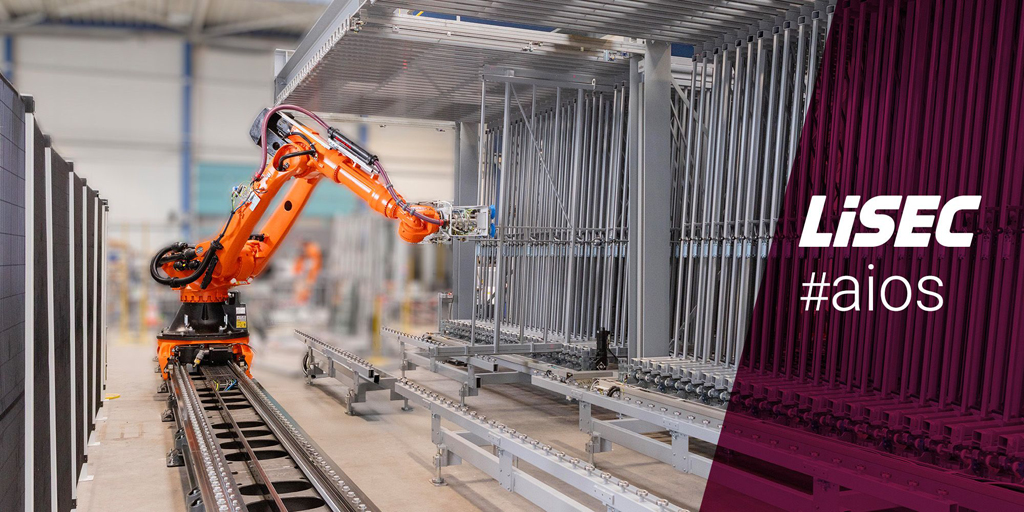

Every minute counts in insulating glass production, especially at the end of the line. With IG-Sort, LiSEC is putting fully automated wet sorting into practice for the first time. Fully automated wet sorting combines efficiency, quality and flexibility, and sets new standards with its technical innovations:

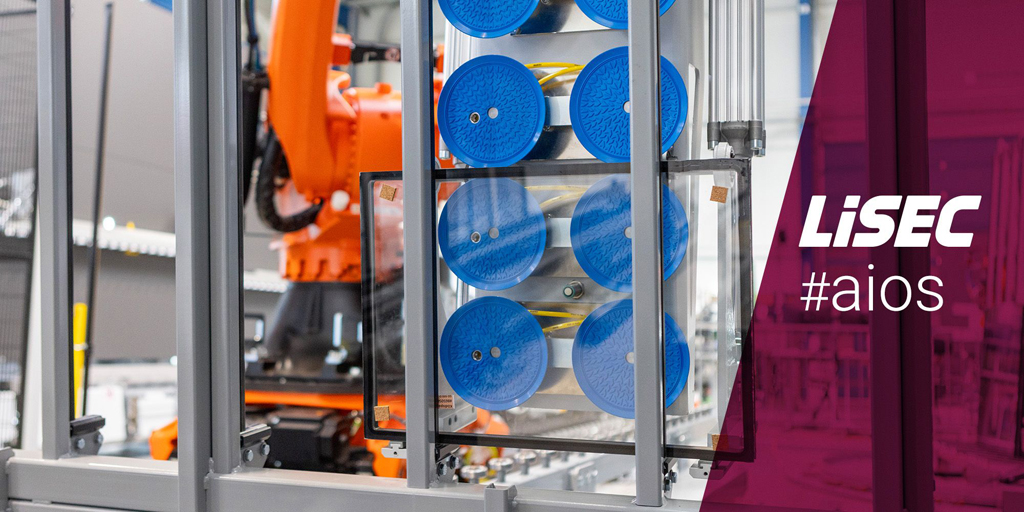

- Efficient curing at a 6 degree angle, preventing deformation, even with large or heavy TPA elements

- Clean curing process, with no material carryover or relative movement of glass panes

- Flexible production logic, independent of run completeness for maximum line utilisation

- High storage density with minimal space requirements thanks to innovative storage compartments with fold-out shelves

The result: a seamlessly integrated, autonomous logistics solution that intelligently decouples production and shipping, and sustainably increases the productivity of the IG line.

“With IG-Sort, we decouple production from shipping and enable our customers to operate their IG lines continuously without waiting times or sorting effort,” said Sebastian Payrleitner, Head of Product Management Logistics, describing the approach.

This transforms logistics from a potential bottleneck into a real productivity factor. IG-Sort: because intelligent logistics makes all the difference.