SEFPRO CARE® hot and cold repairs for the glass industry

Production facilities in the glass industry are capital intensive and require long investment cycles, while market and energy prices have become volatile.

Depending on the market, glass producers are now facing complex choices in energy sources: using current fossil fuels such as natural gas, oxy-gas, or hydrogen and supplementing these with electrical boosting before going to full electric furnaces.

Exposed to these trends, all glass industry (container, flat, specialty, insulation, reinforcement and display) is adapting its industrial strategy to use their current furnaces in the best way and is considering which furnace technology will be used for the next two decades.

This is why SEFPRO CARE® has developed and proposed complete repair solutions to perform hot & cold repairs for any glass market, providing flexibility and reliability in management of such industrial assets as glass furnaces.

Hereafter, the CIP AZS concrete application is detailed, from product characterisation to repair work preparation and application.

CIP cold repairs, a solution applied to container, tableware and specialty furnaces

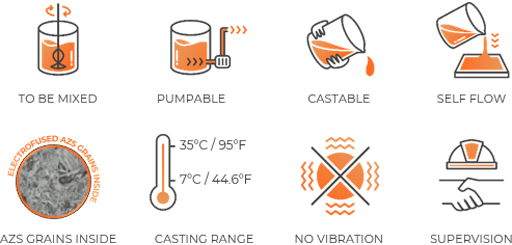

The CIP AZS is a concrete based on AZS fused-cast grains presenting excellent properties in terms of rheology, casting ability and corrosion resistance.

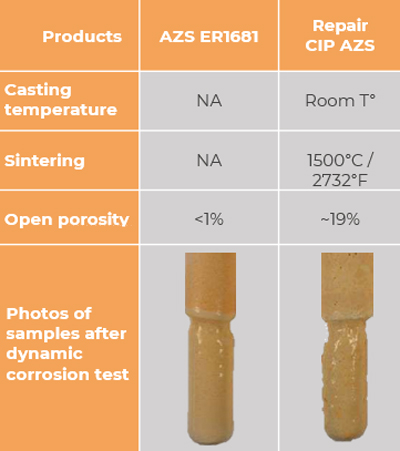

CIP AZS will have more porosity due to the bonding process and will present corrosion resistance equivalent to 60% of a fused-cast block (AZS ER1681) for same furnace conditions (pull rate, glass composition and temperature).

As this product is dedicated to cold repair, the application temperature should not exceed 35°C. The product is setting in cold conditions and requires a 24-hour maturation in its mould before release.

The CIP AZS is especially advantageous when weak areas are discovered during the cold stop of a glass furnace.

Repair work preparation, to reduce the downtime

Furnace area must be clean from any metallic parts and the glass layer on the tank wall must be totally removed to ensure perfect adhesion of the CIP AZS to the existing tank wall.

The quantity of CIP AZS to be installed is a compromise between the residual thickness of the existing fused-cast block, the expected life-time extension from 1 to 4 years, and the furnace acceptable downtime.

Casting can be done on the full length or by zone. This is a decision for glass maker, depending on the wear profile observed after cool down and cleaning the surfaces. No specific joint or expansion gaps are required if casting is done on same kind of AZS products (ie ER1681). The material will behave in a similar way to the fused-cast block with regards to thermal expansion during heating up.

In the presented application case, the decision has been taken to cast per zone of 2-3 blocks, meaning the casting will recover 2-3 fused-cast blocks.

Once cast, the product can be unmoulded 24 hours later. An additional curing time of 48 hours is required to let the product reach its full mechanical strength. Then the heat up process can start according to the heat up curve specified in our data sheet or tailor made if the thickness of the CIP exceeds 250 mm.

Similar preparation can be applied to rebuild glass contact areas, superstructure, tuckstones, or port necks.

SEFPRO CARE®, CIP application for corroded tank wall

The CIP AZS is delivered in bags. One contains the AZS premix (25kg) and the other contains the binder (12.5 kg) for cold application.

The use of a pan-mixer is mandatory, and the given standard operating procedure must be followed strictly to ensure highest product quality. A specific attention must be paid to water quality, as any chemical or bacterial impurities can lead to reactions with cementitious materials and affect product properties (flowability, setting time, corrosion resistance).

Before being pumped or applied manually, the product rheology must be controlled by the means of a flowability test. This test consists of measuring the diameter of a given quantity of mixed CIP AZS 1 min after being poured on a flat surface. We recommend repeating this test frequently during a repair to ensure the consistency of the product, especially when combining various batches (for significant repair from 10 to 60 tons).

SEFPRO CARE© repairs, to reduce CAPEX by approximately 40-50%

Thanks to the good flowability of our CIP AZS, only 7 days were necessary to cast 9.6 tons using buckets.

Figure 6 shows the appearance of CIP AZS 24 hours after casting, which is the recommended maturation time before unmolding.

After demoulding, the CIP AZS will sinter as the furnace heats up in order to reach its final properties. Then production can restart, 30 days after the furnace stop and draining step.

This example illustrates the reactivity given to a customer by providing efficient repair solutions and extending the furnace lifetime by 3 to 4 years during a short cold shutdown of 30 days.

This repair strategy answers three main challenges:

- Cost driven repair: the use of concrete will reduce the CAPEX by approximately 40-50%, compared to the use of AZS fused cast blocks

- Flexible service: SEFPRO Care® maintains a safety stock available worldwide to answer in a matter of days and adapt quickly to your industrial planning

- Fast return to production: even for a cold repair, in this example we highlighted a glass-to-glass interruption limited to 30 days

After a dozen references in Europe since 2010s, with repairs from 1 to 50 tons, SEFPRO Care® is now in full capacity to extend its activities and accompany glass makers in India and Southeast Asia, with recent proven application cases.

Authors: B. Herout, SEFPRO Bonded Market Responsible; L. Coffin,SEFPRO Product Manager; S. Varun, SEFPRO India SEA Regional Technical Referent – Quality leader