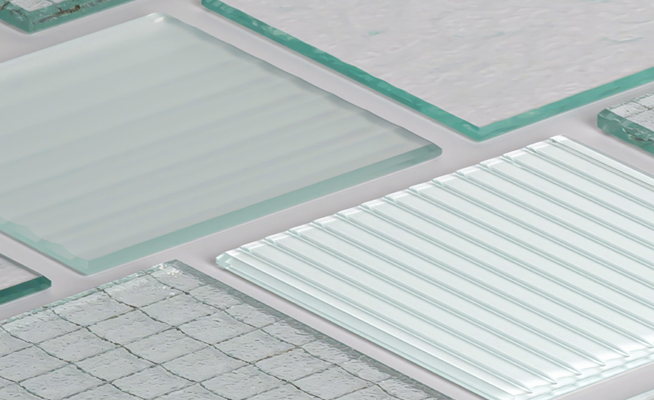

AGC Glass Europe has communicated that the Imagin patterned glass range is now available in four distinct versions, making it suitable for a wide range of applications.

In addition to clear and wired options, AGC now provides certain designs in mat and back-painted versions. The portfolio features 22 standard patterns, including more than 50 patterns upon request, as well as a wide range of sizes and thicknesses.

To top it off, all these products are manufactured in the Volta hybrid glass furnace.

IMAGIN MAT – enhanced privacy

IMAGIN MAT – enhanced privacy

The Imagin Mat range, comprising Imagin Delta Mat and Imagin Flutes Mat, features a high-quality satin finish and delivers enhanced privacy as well as excellent light transmission. AGC’s industrial acid-etching treatment is subject to rigorous quality controls, ensuring uniformity and stability. Imagin Mat products are stain-resistant, making them easy to clean and maintain.

IMAGIN BACK-PAINTED – adding a touch of colour

IMAGIN BACK-PAINTED – adding a touch of colour

Imagin Back-Painted is clear patterned glass featuring a high-quality paint on one side. The range consists of four products combining two colours and two patterns: Imagin Flutes White Light 9003, Imagin Flutes Black Classic 9005, Imagin Raywall 90 White Light 9003 and Imagin Raywall 90 Black Classic 9005.

Imagin Back-Painted products offer versatile design options for use in applications such as kitchen furniture and hotel lobby wall cladding. Imagin Back-Painted is covered by a five-year warranty, provided it is installed using AGC’s FIX-IN glass bonding solutions.

IMAGIN DOMINOS – a newcomer in the IMAGIN CLEAR range

IMAGIN DOMINOS – a newcomer in the IMAGIN CLEAR range

The Imagin Clear range welcomes a new member: Imagin Dominos, a geometric pattern composed of small squares. This new pattern is available in 4, 6 and 8 mm and can be thermally toughened, making it an ideal solution for shower enclosures.

A sustainable range

Last but not least, AGC’s patterned glass range is produced in the Volta furnace at AGC’s Barevka plant in the Czech Republic. This innovative hybrid furnace—50 percent electric and 50 percent fired by a combination of oxygen and gas—not only leads to a significant reduction in direct CO2 emissions, but also supports circularity by using a much higher proportion of recycled materials than typical in the industry.