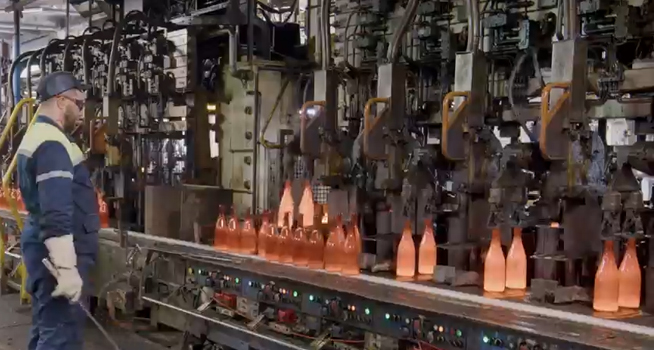

Located in the Marne region, the Oiry plant is the youngest industrial site of Verallia France. With an annual capacity of 200 million bottles, its production is dedicated to carbonated beverages, especially Champagne. The local integration is reflected in its strong contribution to the circular economy, with 90 percent of bottles delivered to Champagne clients being produced locally.

Oiry is also the only industrial site in Europe to produce, every autumn on a dedicated line, large Champagne bottles ranging from 3 to 15 litres. These prestigious formats require special team mobilisation and a high level of technical expertise. This rare know-how, upheld by 170 employees, earned the site the honour of representing the Marne at the “Made in France” Grand Exhibition held at the Élysée Palace in 2023.

For 50 years, the Oiry site has supported the evolution of the Champagne world with a constant drive to offer packaging that is efficient, elegant, and environmentally responsible. This spirit of innovation was recently demonstrated with the launch in 2024 of the Ecova 2 Champenoise, the lightest Champagne bottle in the world. Weighing just 800 grams, it reduces CO2 emissions during production by 4 percent. Developed as the next market standard for the entire Champagne sector, this breakthrough is the result of four years of research conducted at the site.

At Oiry, industrial performance goes hand in hand with energy efficiency. Due to the green and amber hues typical of Champagne bottles, the site incorporates a high proportion of cullet—recycled glass that can make up to 94 percent of bottle composition. This choice helps preserve natural resources while reducing energy consumption (+10 points of cullet = -5percent CO2 emissions and -2.5 percent energy use).

The site also stands out for its exemplary water management, having reduced its consumption by over 90 percent between 2015 and 2019. By the end of 2025, it will become the first glassmaking site to fully meet its water needs through an innovative rainwater harvesting system. Supported financially by the Seine-Normandy Water Agency, this project will collect around 23,000 cubic metres of water annually and reinforce Verallia France’s efforts to reduce its environmental footprint—combining energy efficiency and resource conservation for a more sustainable glass industry.