Among the various ways to reduce the overall energy consumption of glass melting furnaces, increased insulation of furnace superstructures is the first obvious measure to consider, and the easiest to implement. Thicker insulation significantly reduces heat losses, but it also increases the inner refractory temperature. Glassmakers switching to oxy combustion face similar challenges.

How to reduce heat losses in reinforcement glass furnaces

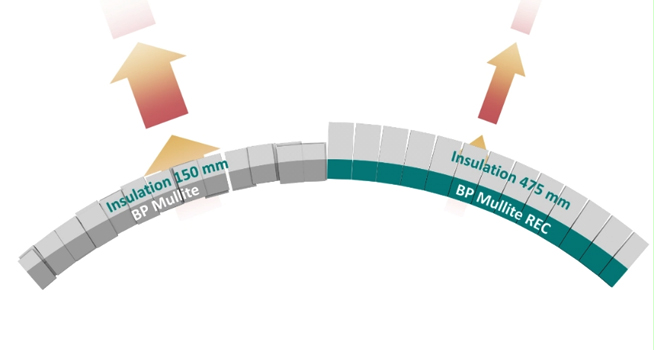

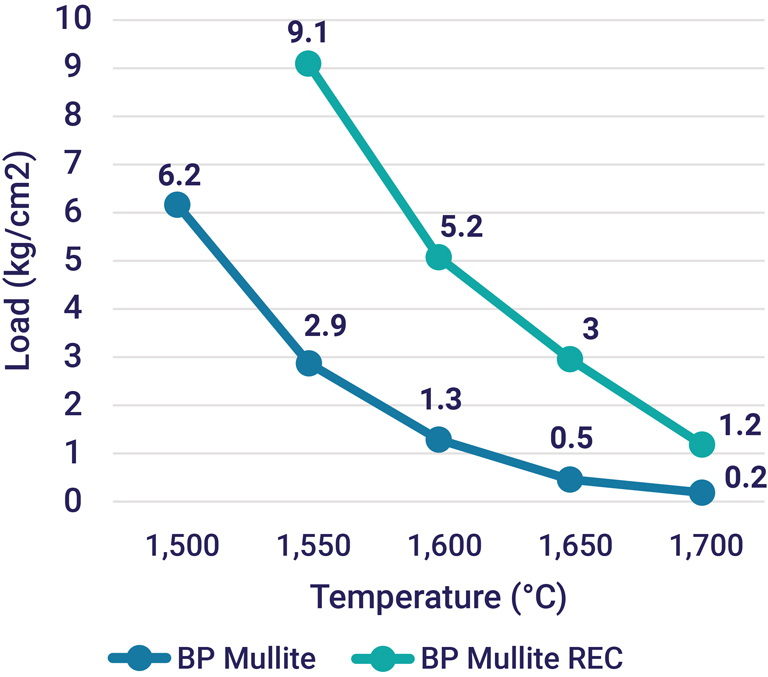

When applied to a glass furnace melter crown, thicker insulation means greater weight and higher constraints on each block of the crown. As the maximum acceptable load decreases with temperature, the risk is consequently exposure of the crown material to a load above its mechanical limit given by the nil creeping curve. The crown may start sagging, and the creeping resistance is challenged.

High creep resistance crown material with the use of BP Mullite REC solution

SEFPRO’s BP Mullite REC superstructure opens the way to new operating conditions that were not previously achievable to reinforcement fibre glass, textile fibre glass, vitroceramic and borosilicate glass furnaces. It allows furnaces to increase the crown temperature by more than 100 degrees Celsius while allowing a safer operation thanks to a much higher creep resistance, up to 6 times at 1,700 degrees Celsius.

A crown material being able to withstand a higher load at higher temperature helps reducing superstructure energy losses by allowing a much heavier insulating package.

Higher refractoriness under load also enables increasing the glass melting temperature in order to reach a higher pull (above 1,550 degrees Celsius and higher) and improve the manufacturing performance.

Refractories integrity and stability during the whole campaign life are the key to high performance melting process, and are particularly critical for the crown application.

BP Mullite REC crown for reinforcement and textile fibre glass melting furnace is especially adapted to oxy-firing combustion and its high flame temperatures.

Thermal losses reduction in reinforcement glass furnaces

A concrete example on how the BP Mullite REC allows 60 percent heat loss reduction while securing the crown against risk of sagging: SEFPRO BP Mullite REC provides safer operation against risk of creeping and reduced the heat losses by more than half with the use of a much thicker insulation. The high refractoriness property of BP Mullite REC ensures a continuous operation without sagging even at very high temperature.

Q&A

Is there any application where BP Mullite REC could not replace the standard BP Mullite material?

BP Mullite REC solution is suitable for all applications where BP Mullite is being currently used without any restriction.

How to understand if BP Mullite REC is required?

Through its numerical simulation service, SEFPRO provides crown stress calculation for any specific design. Such simulation will determine if the foreseen operating conditions does require the use of BP Mullite REC and will also suggest the optimised insulation package to reduce heat losses.