Page 38 - Glass Machinery Plants & Accessories no. 1-2020

P. 38

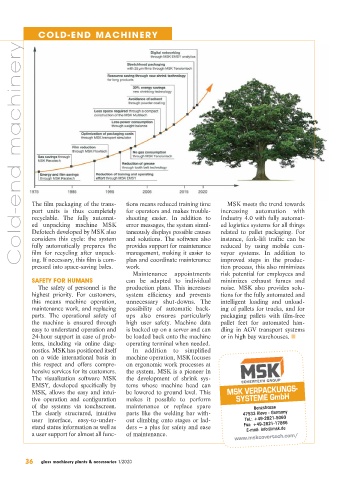

COLD-END MACHINERY

Cold-end machinery

The film packaging of the trans- tions means reduced training time MSK meets the trend towards

port units is thus completely for operators and makes trouble- increasing automation with

recyclable. The fully automat- shooting easier. In addition to Industry 4.0 with fully automat-

ed unpacking machine MSK error messages, the system simul- ed logistics systems for all things

Defotech developed by MSK also taneously displays possible causes related to pallet packaging. For

considers this cycle: the system and solutions. The software also instance, fork-lift traffic can be

fully automatically prepares the provides support for maintenance reduced by using mobile con-

film for recycling after unpack- management, making it easier to veyor systems. In addition to

ing. If necessary, this film is com- plan and coordinate maintenance improved steps in the produc-

pressed into space-saving bales. work. tion process, this also minimizes

Maintenance appointments risk potential for employees and

SAFETY FOR HUMANS can be adapted to individual minimizes exhaust fumes and

The safety of personnel is the production plans. This increases noise. MSK also provides solu-

highest priority. For customers, system efficiency and prevents tions for the fully automated and

this means machine operation, unnecessary shut-downs. The intelligent loading and unload-

maintenance work, and replacing possibility of automatic back- ing of pallets for trucks, and for

parts. The operational safety of ups also ensures particularly packaging pallets with film-free

the machine is ensured through high user safety. Machine data pallet feet for automated han-

easy to understand operation and is backed up on a server and can dling in AGV transport systems

24-hour support in case of prob- be loaded back onto the machine or in high bay warehouses. Q

lems, including via online diag- operating terminal when needed.

nostics. MSK has positioned itself In addition to simplified

on a wide international basis in machine operation, MSK focuses

this respect and offers compre- on ergonomic work processes at

hensive services for its customers. the system. MSK is a pioneer in

The visualization software MSK the development of shrink sys-

EMSY, developed specifically by tems whose machine head can

MSK, allows the easy and intui- be lowered to ground level. This MSK VERPACKUNGS-

tive operation and configuration makes it possible to perform SYSTEME GmbH

of the systems via touchscreen. maintenance or replace spare Benzstrasse

The clearly structured, intuitive parts like the welding bar with- 47533 Kleve - Germany

user interface, easy-to-under- out climbing onto stages or lad- Tel.: +49-2821-5060

stand status information as well as ders – a plus for safety and ease Fax: +49-2821-17866

E-mail: info@msk.de

a user support for almost all func- of maintenance.

www.mskcovertech.com/

36 glass machinery plants & accessories 1/2020