Page 54 - Glass Machinery Plants & Accessories no. 3/2018

P. 54

DEFECT DETECTION

Defect detection

cific feature is very much appre-

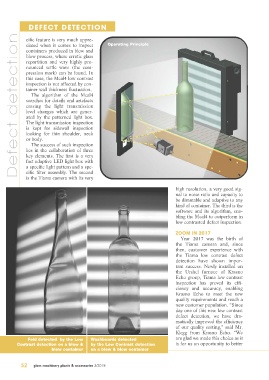

ciated when it comes to inspect Operating Principle

containers produced in blow and

blow process, where erratic glass

repartition and very highly pro-

nounced settle wave (the com-

pression mark) can be found. In

this case, the Mcal4 low contrast

inspection is not affected by con-

tainer wall thickness fluctuation.

The algorithm of the Mcal4

searches for details and artefacts

erasing the light transmission

level changes which are gener-

ated by the patterned light box.

The light transmission inspection

is kept for sidewall inspection

looking for thin shoulder, neck

or body.

The success of such inspection

lies in the collaboration of three

key elements. The first is a very

fast adaptive LED light box with

a specific light pattern and a spe-

cific filter assembly. The second

is the Tiama camera with its very

high resolution, a very good sig-

nal to noise ratio and capacity to

be dimmable and adaptive to any

kind of container. The third is the

software and its algorithm, ena-

bling the Mcal4 to outperform in

low contrasted defect inspection.

ZOOM IN 2017

Year 2017 was the birth of

the Tiama camera and, since

then, customer experience with

the Tiama low contrast defect

detection have shown impor-

tant success. Newly installed on

the Urshel furnace of Krasno

Echo group, Tiama low contrast

inspection has proved its effi-

ciency and accuracy, enabling

Krasno Echo to meet the new

quality requirements and reach a

new customer population. “Since

day one of this new low contrast

defect detection, we have dra-

matically improved the efficiency

of our quality sorting,” said Mr.

Klegg from Krasno Echo. “We

Fold detected by the Low Washboards detected are glad we made this choice as it

Contrast detection on a blow & by the Low Contrast detection is for us an opportunity to better

blow container on a blow & blow container

glass machinery plants & accessories 3/2018

52