Page 60 - Glass Machinery Plants & Accessories no. 4/2018

P. 60

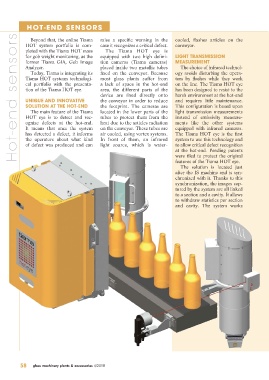

HOT-END SENSORS

Hot-end sensors

Beyond that, the online Tiama raise a specific warning in the cooled, flashes articles on the

HOT system portfolio is com- case it recognizes a critical defect. conveyor.

pleted with the Tiama HOT mass The Tiama HOT eye is

for gob weight monitoring, as the equipped with two high defini- LIGHT TRANSMISSION

former Tiama GIA, Gob Image tion cameras (Tiama cameras) MEASUREMENT

Analyzer. placed inside two metallic tubes The choice of infrared technol-

Today, Tiama is integrating its fixed on the conveyor. Because ogy avoids disturbing the opera-

Tiama HOT systems technologi- most glass plants suffer from tors by flashes while they work

cal portfolio with the presenta- a lack of space in the hot-end on the line. The Tiama HOT eye

tion of the Tiama HOT eye. area, the different parts of the has been designed to resist to the

device are fixed directly onto harsh environment at the hot-end

UNIQUE AND INNOVATIVE the conveyor in order to reduce and requires little maintenance.

SOLUTION AT THE HOT-END the footprint. The cameras are This configuration is based upon

The main feature of the Tiama located in the lower parts of the light transmission measurements

HOT eye is to detect and rec- tubes to protect them from the instead of emissivity measure-

ognize defects at the hot-end. heat due to the articles radiation ments like the other systems

It means that once the system on the conveyor. These tubes are equipped with infrared cameras.

has detected a defect, it informs air cooled, using vortex systems. The Tiama HOT eye is the first

the operators about what kind In front of them, an infrared system to use this technology and

of defect was produced and can light source, which is water- to allow critical defect recognition

at the hot-end. Pending patents

were filed to protect the original

features of the Tiama HOT eye.

The solution is located just

after the IS machine and is syn-

chronized with it. Thanks to this

synchronization, the images cap-

tured by the system are all linked

to a section and a cavity. It allows

to withdraw statistics per section

and cavity. The system works

glass machinery plants & accessories 4/2018

58