Page 84 - Glass Machinery Plants & Accessories no. 2/2017

P. 84

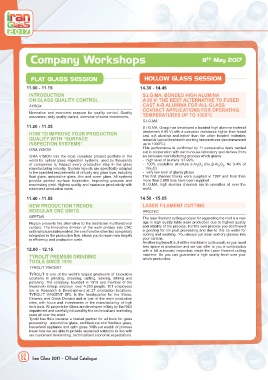

Company Workshops 8 May 2017

th

FLAT GLASS SESSION HOLLOW GLASS SESSION

11.00 - 11.15 14.30 - 14.45

INTRODUCTION S.I.G.MA. BONDED HIGH ALUMINA

ON GLASS QUALITY CONTROL A 95 V: THE BEST ALTERNATIVE TO FUSED

AYROX &$67 ǹ Ǻ $/80,1$ )25 $// */$66

Normative and economic reasons for quality control, Quality CONTACT APPLICATIONS FOR OPERATING

assurance, daily quality control, overview of some instruments. TEMPERATURES UP TO 1300°C

S.I.G.MA.

11.20 - 11.35 S.I.G.MA. Group has developed a bonded high alumina material

(trademark A 95 V) with a corrosion resistance higher than fused

HOW TO IMPROVE YOUR PRODUCTION FDVW Į ȕ DOXPLQD DQG EHWWHU WKDQ WKH RWKHU ERQGHG PDWHULDOV

QUALITY WITH “SURFACE tested at typical forehearth working temperatures (recommended

INSPECTION SYSTEMS” up to 1300°C).

ISRA VISION 7KLV SHUIRUPDQFH LV FRQ¿UPHG E\ FRPSDUDWLYH WHVWV FDUULHG

out in cooperation with our in-house laboratory and derives from

ISRA VISION has the most complete product portfolio in the an exclusive manufacturing process which grants:

world for optical glass inspection systems, used by thousands - high level of alumina: 97-99%

of companies to inspect every production step in the glass FU\VWDOOLQH VWUXFWXUH Į $O O 1R ȕ $O O , No 3-4% of

2 3

2 3

PDQXIDFWXULQJ LQGXVWU\ 6\VWHP OD\RXWV DUH VSHFL¿FDOO\ DGDSWHG Na O)

2

WR WKH VSHFL¿HG UHTXLUHPHQWV RI YLUWXDOO\ DQ\ JODVV W\SH LQFOXGLQJ - very low level of glassy phase

ÀRDW JODVV DXWRPRWLYH JODVV WKLQ DQG FRYHU JODVV $OO V\VWHPV 7KH ¿UVW FKDQQHO EORFNV ZHUH VXSSOLHG LQ DQG IURP WKHQ

provide perfect surface inspection, improving process and more than 2,000 tons have been supplied.

maximizing yield. Highest quality and maximum productivity with S.I.G.MA. high alumina channels are in operation all over the

minimized production costs. world.

11.40 - 11.55 14.50 - 15.05

NEW PRODUCTION TRENDS: LASER FILAMENT CUTTING

MODULAR CNC UNITS IPROTEC

NEPTUN 7KH ODVHU ¿ODPHQW FXWWLQJ SURFHVV IRU VHSDUDWLQJ WKH PRLO LV D QHZ

Neptun presents the alternative to the traditional multifunctional age in high quality table ware production due to highest quality

centers. The innovative division of the work phases into CNC and stability of the process. For the new process you don’t need

units which are independent the one from the other but completely a grinding for rim post processing and due to this no water for

LQWHJUDWHG LQ WKH SURGXFWLRQ ÀRZ DOORZV \RX WR UHDFK QHZ WDUJHWV cooling and washing. You always put clean and dry glasses into

LQ HI¿FLHQF\ DQG SURGXFWLRQ FRVWV your cartons.

$QRWKHU ELJ EHQH¿W LV WKDW WKH PDFKLQH LV TXLWH VPDOO VR \RX QHHG

less space in production and we can offer to you a combination

12.00 - 12.15 ZLWK D IXOO DXWRPDWLF LQVSHFWLRQ LQVLGH WKH /DVHU ¿ODPHQW FXWWLQJ

machine. So you can guarantee a high quality level over your

TYROLIT PREMIUM GRINDING whole production.

TOOLS SINCE 1919

TYROLIT VINCENT

TYROLIT is one of the world's largest producers of innovative

solutions in grinding, dressing, cutting, sawing, drilling and

polishing. The company, founded in 1919 and member of the

Swarovski Group, employs over 4.250 people, 101 employees

are in Research & Development at 27 production locations.

TYROLIT VINCENT SRL is the headquarter for the Stone,

Ceramic and Glass Division and is one of the main production

sites, with focus and investments in the manufacturing of high

tech tools. All projects for Glass are developed in Italy by the R&D

department and carefully followed by the technical and marketing

team all over the world.

Tyrolit has thus become a trusted partner for all tools for glass

processing: automotive glass, architectural and furniture glass,

household appliance and optic glass. With our wealth of process

know-how we are able to provide sustained solutions in line with

our customers' demanding , technical and economic expectations.

82 Iran Glass 2017 - Official Catalogue